Element 30 Manual

Original instructions

Jan 2015

14

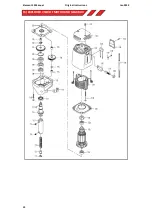

PARTS LIST

1

RD43131

Screw M5 X 16 CSK HD

2

2

RD45607

CSK Washer

2

3

RDA3032

Guard Support

1

4

RDA3031

Slide Channel

1

5

RDA4201

Screw M4 X 14 BTTN HD

2

6

RDA3029

Element 30 Guard

1

7

RDA2002/1 (110) -‐ RDA2002/3 (230)

Motor Assembly

1

8

RD45624

Needle Bearing HK3516

1

9

RDA3013

Bearing Bracket

1

10

RDA3011/1 (110V) -‐ RDA3011/3 (230V)

Magnet

1

11

RD4078

M8 Washer

2

12

RD4079

M8 Spring Washer

2

13

RD4277

Screw M8 X 50 CAP HD

2

14

RD4207

M6 Spring Washer

4

15

RD4098

Screw M6 X 20 CAP HD

4

16

RDA4005

Cable Bush

1

17

RDA4021

Screw M4 X 8 BTTN HD

17

18

RDA3001

Main Housing

1

19

RD45622

Straight Pin

2

20

RDA3026

Right Side Panel

1

21

RD4312

Grub Screw M6 X 12

5

22

RDA3092

Bush

2

23

RDA4006

Capstan Washer

2

24

RDA4004

Circlip

2

25

RDA2004

Coolant Bottle Assembly

1

26

RDA4029

Screw M6 X 16 CAP HD

1

27

RD33105

Gib Strip Support

1

28

RDA3038

Gib Strip 17.5mm

1

29

RDA3035

Slide

1

30

RD4092

M5 Shake Proof Washer

4

31

RD4091

Screw M5 X 22 CAP HD

4

32

RDA3027

Rack

1

33

RDA3037

Gib Strip 13.5mm

1

34

RDA2016

Internal Chain

1

35

RDA4204

Screw M3 X 8 CSK HD

8

36

RDA4205

M3 Nut

4

37

RDA3045

Cable Chain Attachment

2

38

RDA4206

Screw M4 X 12 CSK HD

2

40

RDA5008

Handle Insert

1

41

RD4206

Screw M6 X 40 CAP HD

2

42

RD4069

M4 Washer

1

43

RD4068

M4 Nut

2

44

RD45604

Earth Label

1

45

RDA3025

Left Side Panel

1

46

RDA3012

Capstan Axel

1

47

RD43117

Cable Clamp

1

48

RDA4207

Screw M4 X 14 CAP HD

2

49

RDA2008

Capstan Arm

3

50

RDA3015

Capstan Hub

1

51

RDA2020/1 (110V) -‐ RDA2020/3 (230V)

Pcb Assembly

1

52

RDA2007/1 (110V) -‐ RDA2007/3 (230V)

Control Panel Assembly

1

53

RDA3071 (110V) -‐ RDA3072 (230V)

Power Cable

1

54

RD4329

Safety Belt

1

55

RD4088

4mm Hexagonal Spanner

1

56

RD43099

Chuck

1

57

RD33153

Adapter

1

58

RDA3105

Safety Glasses

1

59

RD4152

3mm Hexagonal Spanner

1