USER'S AND

MAINTENANCE

MANUAL

Date:

01/31/2020

Code

MAN D185T4F-DB

ENG

Air Compressor : D185T4F-DB

Revision 03

Copyright © 2014, ROTAIR S.P.A. - All rights reserved

.

This manual is intellectual property of ROTAIR S.P.A.

Its full or partial reproduction is forbidden under any form, on any support and by any means, without the

written authorization by ROTAIR S.P.A.

Page

19/59

4.3 Residual risk

Avoid standing in front of the compressed air discharge ports. The direct exposure to the air

stream may cause severe injuries due to the strength and speed of the compressed air.

The machine must operate outdoors because of the presence of the engine and the relevant

exhaust gases.

DO NOT operate the machine in an indoor environment that has an atmosphere containing

vapors or mixtures of corrosive or explosive gases.

When performing demolition, drilling, sandblasting activities, or any other operation that generates dust, the

tool needs to be connected to the compressor through a pressure-resistant hose of sufficient length to keep

the machinery away from the work area, thus preventing clogging of both the air filters mounted on the unit or

the radiator for the cooling of the lubrication and engine cooling systems. Even in this case, an educated user

will operate the machinery an appropriate distance away from the work area.

The machinery has been designed and built to work with the hood closed and, consequently, DO NOT keep

it open when the engine is on because besides generating harmful sound emissions, the required internal

ventilation would be interrupted, and possible damage to the machine may result.

Make sure that the hood is closed and the latches located on the rear side of the air compressor are latched.

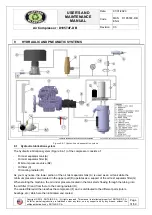

Figure 4.3-1 Engine compartment hood latches

When selecting the hoses to connect the machinery to the tool, make sure that they are sized appropriately,

taking into account their length, the volume of air which needs to pass through them, and the service

pressures. If the hoses are too small in diameter or too long in length, the air flow would be interrupted, with

subsequent loss of load and poor performance of the tool.

The hoses, which transmit compressed air from the machinery to the tool or to any device applied, are to be

provided with a valve located at the end which is connected to the tool. The

air

valve shall be held closed

during the connection of the hoses to both the machinery and the tool in order to prevent an accidental

opening of the

air

valve on the machine side and to prevent an uncontrolled whipping of the hoses, which

may cause injuries. Before disconnecting any hose, make sure there is no pressure inside.