USER'S AND

MAINTENANCE

MANUAL

Date:

01/31/2020

Code

MAN D185T4F-DB

ENG

Air Compressor : D185T4F-DB

Revision 03

Copyright © 2014, ROTAIR S.P.A. - All rights reserved

.

This manual is intellectual property of ROTAIR S.P.A.

Its full or partial reproduction is forbidden under any form, on any support and by any means, without the

written authorization by ROTAIR S.P.A.

Page

24/59

7

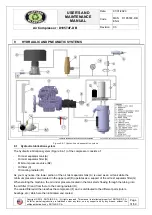

MACHINERY COMPONENTS

This unit D185T4F-DB is a single-phase, silenced oil injection screw

air

compressor. The engine is

an

internal-combustion, fueled by gas

or diesel,

and is connected to the compressor by a flexible coupling.

7.1 Body

The body is built entirely out of galvanized sheet iron. Panels can easily be removed to allow convenient

access to the main machine parts. The machine is entirely lined with sound absorbent and fire-retardant

material. Special holes have been created in the panels forming the body, complete with baffles, which allow

the cool air necessary for engine and compressor cooling, to be sucked in from one side and the heated air

to be expelled from the other side. These baffles have been carefully designed in terms of size and shape so

as to allow the most efficient internal ventilation of the machine. Therefore, it is advisable to ensure that these

openings are kept free from debris and remain undamaged.

All of the parts of the body have been treated

with a special painting process which guarantees excellent finishing quality

,

together with maximum impact

and rust resistance.

7.2 Engine

The unit is equipped with a diesel engine whose features are described in Section 2.

As related to the user's and maintenance instructions, refer to the manual provided by the

m

anufacturer

and

the enclosed

documentation relevant to this machinery.

7.3 Compressor unit

It is completely manufactured in the ROTAIR factory and consists of a central body cylinder inside

,

which

is

fitted

with

two screw rotors with asymmetric section, a male one with 5 lobes and female one with 6 lobes.

The cylinder is closed at the ends by two head sections which contain the bearings

that

bear the radial and

axial loads created by the air compression. A series of channels inside the cylinder and heads deliver the oil

to the various components. The distribution of the lubricant

serves to lubricate the bearings and maintain a

coating of oil between the rotors and the bearings themselves as well as the internal cylinder walls, thereby

promoting compression resistance. Another important function of the oil injected between the rotors is that of

absorbing the heat generated by the compression

of the air.

The compressed air supplied by this compressor

is free of any pulsations

,

and compression comes about axially.

A "regulator" unit is mounted on the compress

or

unit

to regulate the quantity of air taken in according to

the amount of air consumed. A double-stage filter mounted on the top of this unit guarantees maximum

purity of the suctioned air.

7.4

Oil mist s

eparator tank

The oil mist separator tank consists of a pressurized container, and, due to its construction features, it is

exempt from the annual I.S.P.E.L. inspection and is supplied with a conformity certificate issued by the

manufacturer. The identification and inspection details are stamped on a plate which is welded to the

machine.

The lid features the following elements: safety valve for overpressure, a thermal switch which intervenes if the

temperature inside the tank exceeds 100°C (212°F), and valves which regulate the maximum and minimum

pressure of the machine.