USER'S AND

MAINTENANCE

MANUAL

Date:

01/31/2020

Code

MAN D185T4F-DB

ENG

Air Compressor : D185T4F-DB

Revision 03

Copyright © 2014, ROTAIR S.P.A. - All rights reserved

.

This manual is intellectual property of ROTAIR S.P.A.

Its full or partial reproduction is forbidden under any form, on any support and by any means, without the

written authorization by ROTAIR S.P.A.

Page

32/59

From the compressor (F), the oil

is

mixed with the compressed ai

r from the

check valve (8)

and

is sent to the

separator tank (A), where, through a forced centrifugal circuit,

the first separation of the

compressed air

from

the

oil

occurs. The resulting compressed air leaves the separator tank through the oil mist separator filter (G),

which will provide a second and last separation of the

oil

from the

compressed air

.

Even though the separating filter (G) separates the oil from the air, it is worth pointing out that a limited quantity

of oil manages to penetrate inside the

oil mist separator

filter and deposits on the lower portion of the filter

itself.

The oil is sucked into the tubing where a calibrated nozzle (7) and a check-valve (8) will route it to the compressor

(F). The check valve (8) shall prevent the oil from retu

rn

ing to the

oil mist

separator filter (G) when the

machine is stopped.

Attention

:

The oil filter (C) is provided with a “by-pass” valve which allows the oil to circulate in case it is

clogged. In such case, the oil shall circulate regularly without being filtered.

WARNING: The filter therefore needs to be replaced at regular intervals, as specified in the

maintenance program.

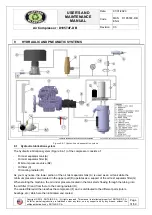

9.2 Pneumatic system

The pneumatic system (Figure 8.4-1) includes:

-

start/work valve (1)

-

suction filter (6)

-

suction adjustment valve (2)

-

compressor (F)

-

separator tank (A)

-

oil mist

separator filter (G)

-

min. pressure and check valves integrated i

n

the valve (B2)

-

air valve

(11)

-

m

ax. pressure valve (4)

The compressor suction air, after passing through the air filter (6), reaches the suction adjuster (2) and then

the compressor (F), which, after compressing it, directs it together with the injected oil into the separator tank

(A). Here, the

oil

is separated from the

air

. This process, as indicated above, is made by centrifugal force and

then by the use of the oil mist separator filter (G).

Once the air is separated from the oil, it is routed to the minimum pressure valve (B2) which opens only when

the pressure in the tank has reached the established value.

It is in any case a good practice not to use tools that, with their excessive consumption, may cause the

lowering of the pressure in the tank under 5-5.2 bar

/

72.5-75psi. Lengthened working conditions below 5

bar

/

72.5 psi may create insufficient separation of

the

oil from the air with subsequent excessive consumption

of lubricant. Furthermore, the minimum pressure valve (B2) acts as a check valve, thus preventing the return

of compressed air into the unit from piping or tools connected to the machinery.

WARNING:

P

ressure tank