USER'S AND

MAINTENANCE

MANUAL

Date:

01/31/2020

Code

MAN D185T4F-DB

ENG

Air Compressor : D185T4F-DB

Revision 03

Its

n

Copyright © 2014, ROTAIR S.P.A. - All rights reserved

.

This manual is intellectual property of ROTAIR

S.P.A. full or partial reproduction is forbidden under any form, on any support and by any means, without the

writt

e

authorization by ROTAIR S.P.A.

Page

44/59

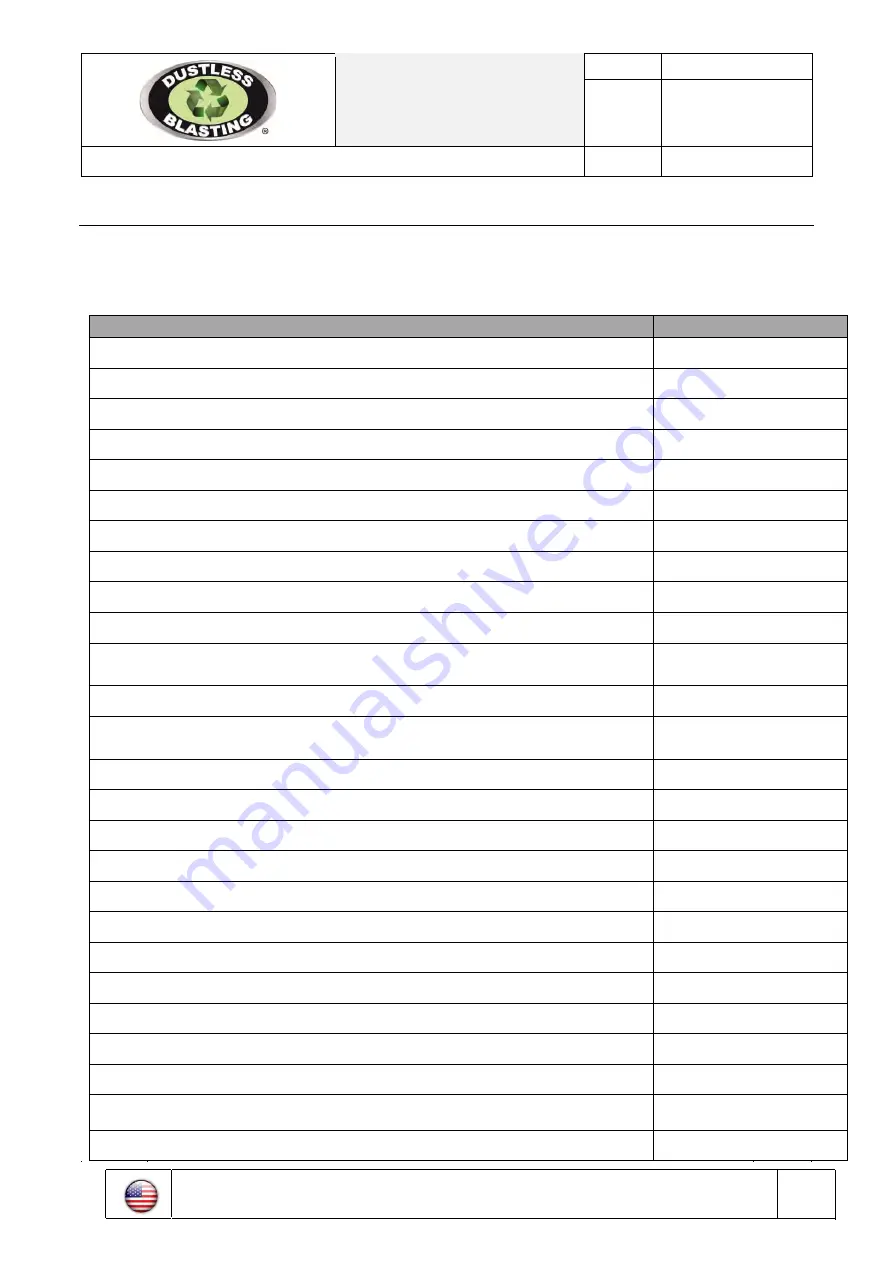

13.2 Maintenance program

In this program are listed all the

maintenance items

and the frequency

of which they must be

executed

on the various components of the machine. Such

maintenance is

essential for the proper functioning of

the machine and its mechanical durability over time.

RECOMMENDED OPERATIONS

FREQUENCY

Check

the

compressor

oil level

Daily

Check engine oil level (refer to the manufacturer's manual)

Daily

Check Coolant Level

Daily

Check fuel level and top

off

(if necessary)

Daily

Check oil or fuel leakage

Daily

Check operation indicator

\warning

lights

Daily

Check the readability of measuring instruments

Daily

General cleaning operations

Daily

C

heck for

obstructions to the ventilation system

Daily

C

heck

air filter in dusty work conditions

Daily

Check operation trailering lights and license plate lights (only for the approved

road version)

Daily

C

heck

the

c

ompressor

air filter

W

eekly

C

heck

the engine air filter

(Ref. Manual of the engine

manufacturer)

Check

the battery electrolyte level

Monthly

Check tire pressure

Monthly

Check

belt tension

Three months

Check s

peed control

s at

the minimum and maximum engine

RPM

Three months

C

heck

the

operation

of the safety valve

Three months

Clean the oil cooler

Three months

C

heck the oil recovery

nozzle

Three months

Drain the fuel tank

Three months

Replace diesel

fuel

pre-filter

Every 500 hours

C

heck

the

operation

of the braking system

Three months

Check the parking brake if equipped

Three months

Change engine oil

Ref. Manual of the engine

manufacturer

Replace

compressor

oil filter

After the first 50 hours