USER'S AND

MAINTENANCE

MANUAL

Date:

01/31/2020

Code

MAN D185T4F-DB

ENG

Air Compressor : D185T4F-DB

Revision 03

Copyright © 2014, ROTAIR S.P.A. - All rights reserved

.

This manual is intellectual property of ROTAIR S.P.A.

Its full or partial reproduction is forbidden under any form, on any support and by any means, without the

written authorization by ROTAIR S.P.A.

Page

51/59

13.4

-

6

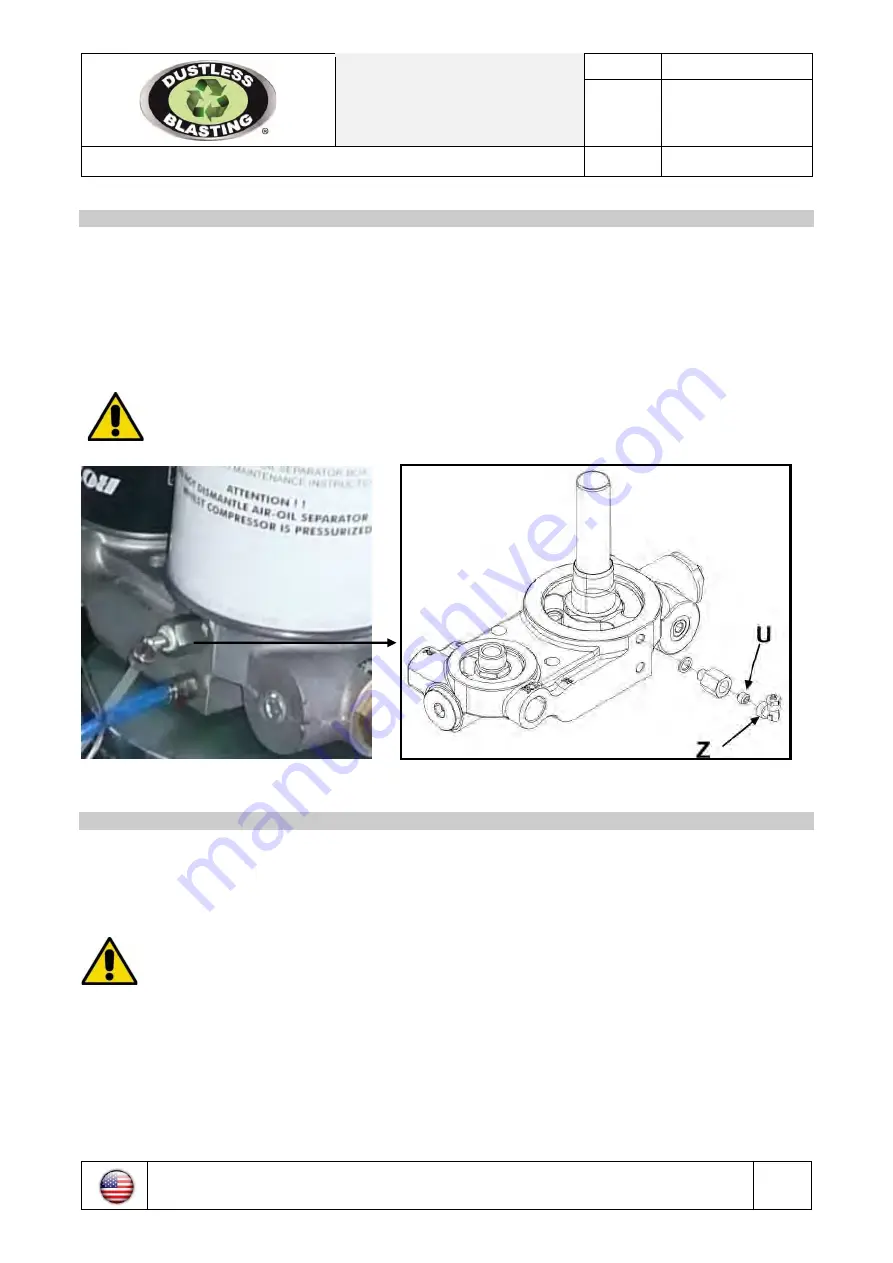

CHECKING AND CLEANING

THE

OIL RECOVERY NOZZLE

Check and clean the oil recovery system. Should you find a leak of oil mist mixed with compressed

air, operat

e

as follows (Figure 13.4-4)

:

1)

Remove the fitting located at the center of the tank (Letter Z)

2)

Inside the fitting (Letter Z) is a nozzle (Letter U). Make sure that its calibrated hole is not blocked

(blow it out with compressed air)

3)

Reinstall the fitting

WARNING:

During normal operation of the compressor, the fitting in the pipe is

4)

transparent (Z).You will notice a certain amount of oil flow from the fitting (Z)

towards the

head of the compressor

Figure 13.4-4 Nozzle oil recovery

13.4

-

7

DRAINING

THE FUEL TANK

The draining of the fuel tank is recommended at times in an effort to remove water and contaminants that

may collect in the tank during normal operation and filling. Avoid refueling with cans because these may

contain traces of water which, being heavier than the diesel fuel, are at the bottom of the can and thus can

be introduced into the fuel tank of the machine.

Periodically open the fuel tank drain to remove the water from the fuel tank. Failure to

periodically drain the tank can allow small amounts of water to be injected into the engine.

It is also advisable to refuel at the end of the work shift to prevent the varying temperature range of the tank

walls from allowing condensation to form in the fuel tank overnight.

In conjunction with draining water from the fuel tank, replacing the fuel filter at the same time can help to

eliminate water from the entire fuel system.