33

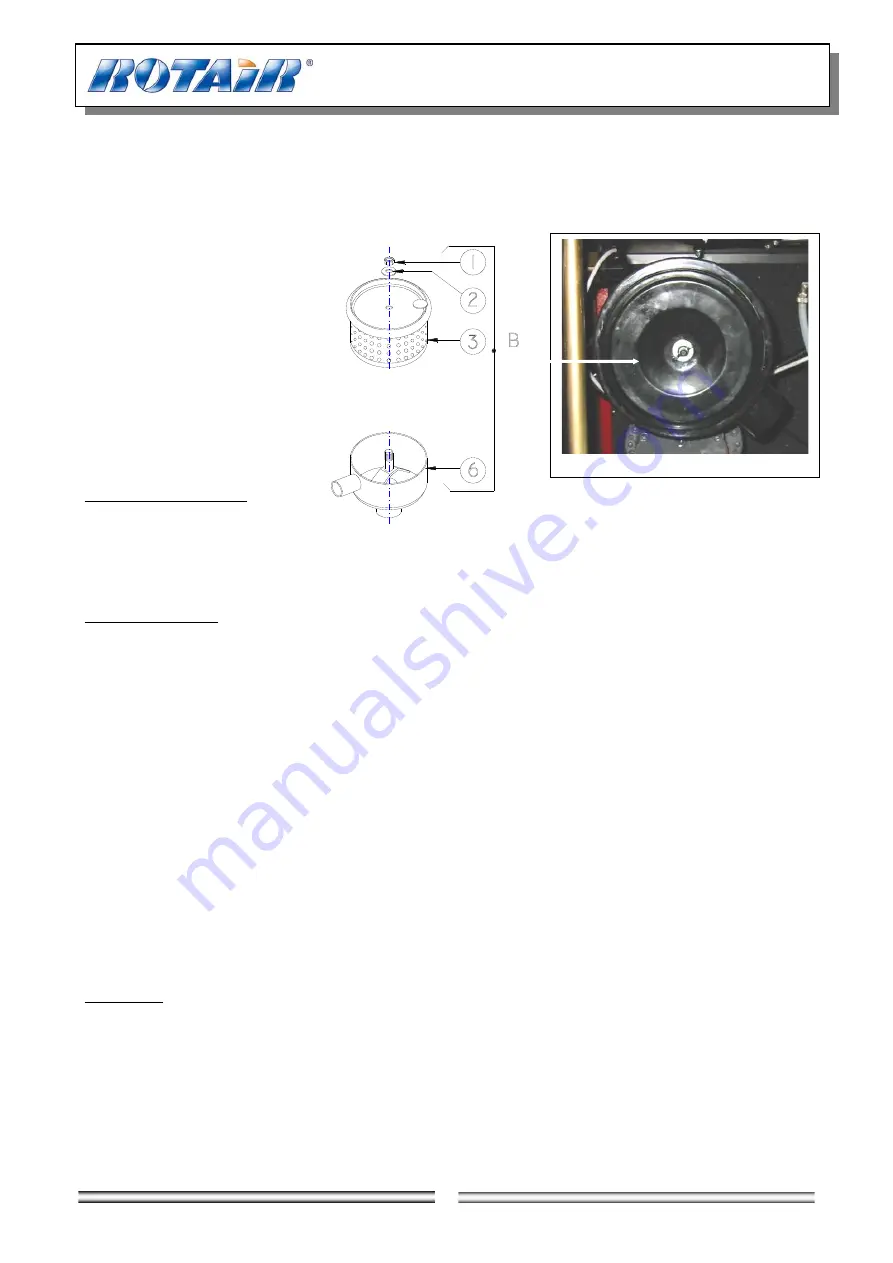

-- 12.11) AIR FILTER MAINTENANCE

--

The compressor life and efficiency

greatly depend on an accurate

maintenance of the air filter. A

clogged filter reduces the efficiency

and causes an early wear of the

compressor.

In normal environmental conditions

clean the air filters every 100 hours

work and change the air filter after

500 hours work. In very dusty

environmental conditions clean as

often as required.

FILTER DISASSEMBLY

1. Unscrew nuts

2. Extract the closing flange

3. Extract the air filter

FILTER CLEANING

Accurately blow the air filter inside out. The above operations should be carried out in the reverse order

to fit them back again.

-- 12.12) SUCTION FILTER AND ITS MAINTENANCE --

RVK compressors have been designed and made to operate in an environment at a max. temperature of

40°C;

should the machine be installed in a small ill-ventilated room because you have no other choice, it will

be necessary to make a ventilation duct for air suction and a second duct for letting hot air out. Both

ducts shall be connected with the outside and set in such a way as to prevent suction air from mixing

with exhaust air. They shall have an adequate size with open-radius bends. An incorrect sizing would

reduce ventilation and cause compressor overheating.

The room shall be well aired , clean and as close as possible to the distribution mains network. Should

the compressor operate in a very dusty environment, clean air shall flow freely: this can be achieved by

replacing the filter often enough (on the vent).

A dirty clogged filter reduces and slows down the quantity of air being sucked in necessary for

ventilation with a consequent harmful overheating of the unit.

WARNING:

type, density and thickness of the filter have been designed and selected not to brake the

sucked in air too much. Therefore the spares shall always be original ROTAIR S.P.A. spares. Should

other materials be used the guarantee on the machine will become null and void.

The machine shall be installed by leaving free space around it for ordinary and extraordinary

maintenance operations.

Fig. 14