5

B M W

B M W

B M W

B M W

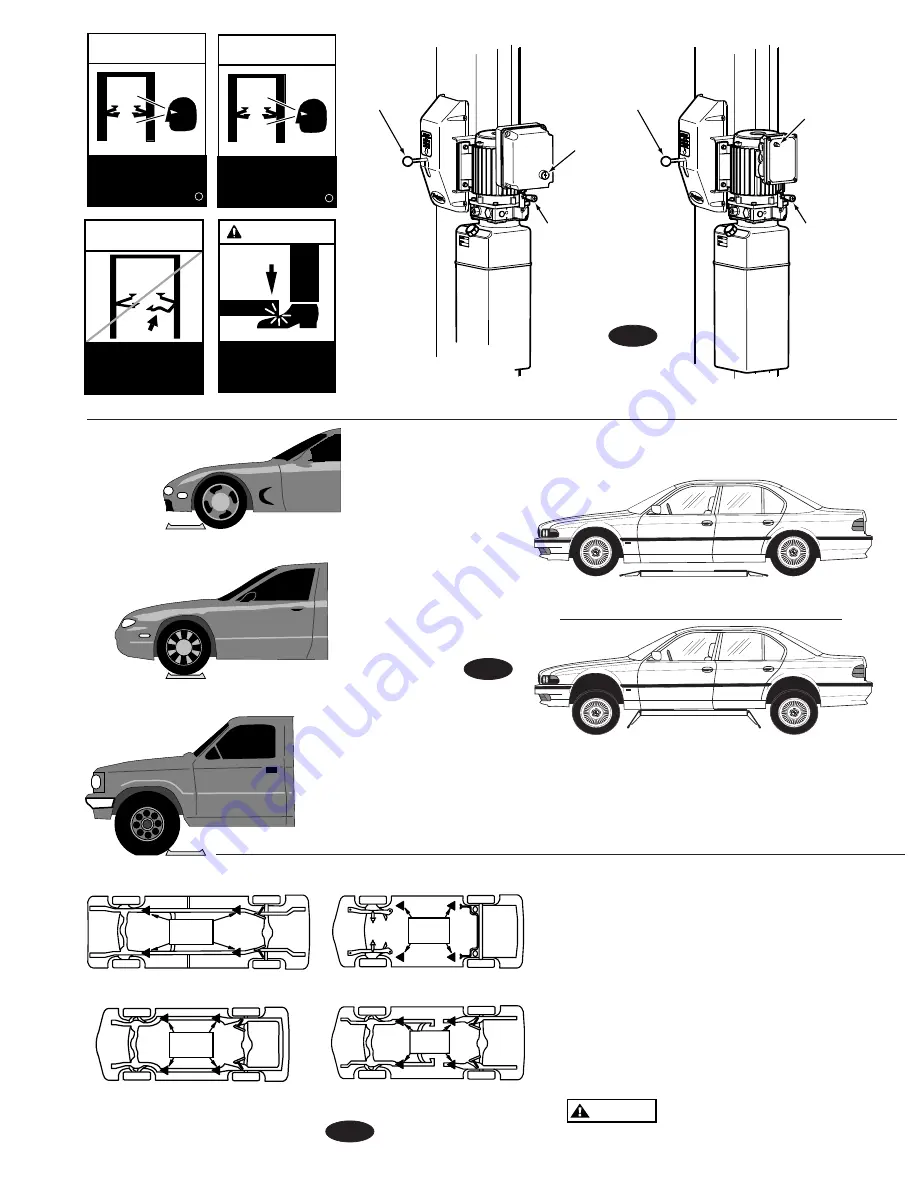

Vehicle Spotting Position

Vehicle Loading Position

FRONT

LIFT

POINTS

FRONT

LIFT

POINTS

FRONT

LIFT

POINTS

FRONT

LIFT

POINTS

Pickup Truck

Perimeter Frame

Unitized Body

Stub Frame

Keep feet

clear of lift

while lowering.

©

WARNING

SAFETY

INSTRUCTIONS

Do not operate

a damaged lift.

©

SAFETY

INSTRUCTIONS

Proper maintenance

and inspection

is necessary

for safe operation.

c

SAFETY

INSTRUCTIONS

Proper maintenance

and inspection

is necessary

for safe operation.

c

Less than 105"

wheelbase:

position left front

wheel on approach

side of wheel dish.

105"-127"

wheelbase:

position left front

wheel in wheel

dish.

Larger than 127"

wheelbase:

position left front

wheel just forward

of wheel dish.

NOTE: Some vehicles may have the manufacturer's

Service Garage Lift Point locations identified by

triangle shape marks on it's undercarriage. Also,

there may be a label located on the right front door

lock face showing specific vehicle lift points. If the

specific vehicle lift points are not identified, refer to

the "Typical Lift Points" illustrated herein. ALWAYS

follow the operating instructions supplied with the

lift.

NOTE: This style lift is not

recommended for pickup trucks or

vehicles with truck frames.

Typical Lifting Points

Fig. 5

CAUTION

Fig. 6

Latch

Release

Raise

Switch

Lowering Valve

Handle

Latch

Release

Raise

Switch

Lowering Valve

Handle

Fig. 4

Summary of Contents for SPOA7 Series

Page 10: ...10 NOTES...

Page 11: ...11 NOTES...