6

7

6

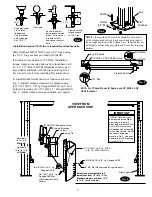

Latch Control Plate

1/4"-20NC x 1-3/4"

HHCS & Nylon Locknut

Clevis Pin &

Retaining Rings

Locking Latch

Air Cylinder

Clevis

Air Cylinder

Bracket

Lowering Switch

Union Tee

To Left Column

Air Cylinder

To Main

Air Supply

1/4" Male

Connector

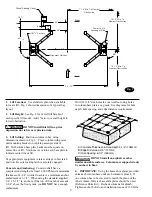

Fig. 13

(2) 5/16" x 3/8" Lg.

Pan Head Screw &

5/16" Ext. Tooth

Lockwashers

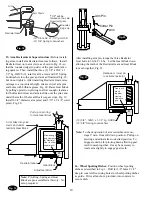

11. Locking Latch & Air Cylinders:

A)

To install cylinder, first slip dampening spacer over

rod with rod in retracted position as shown below, Fig. 12.

B)

Put locknut on threaded shaft and run it down to the

dampening spacer.

C)

Let rod extend and thread locknut down 1-1/2 more

turns.

D)

Screw Bracket Clevis onto shaft, position, and tighten

locknut securely, Fig. 12.

E)

Slide latch control plate into top cylinder Bracket

Clevis.

F)

Insert Pivot Pin through hole in bracket and Latch

Plate. Install one clip ring on each side of Upper Pin.

G)

Extend cylinder where column Pivot Bracket is to be

mounted.

H)

Slide one side of lower Pivot Pin (pre-installed &

fixed in cylinder) into one half of the column Pivot Brack-

et. Install Pivot Bracket into column using (2) 1/4"-20NC

x 3/8" lg. PHMS, Fig. 12.

I)

Install other half of Pivot Bracket the same way.

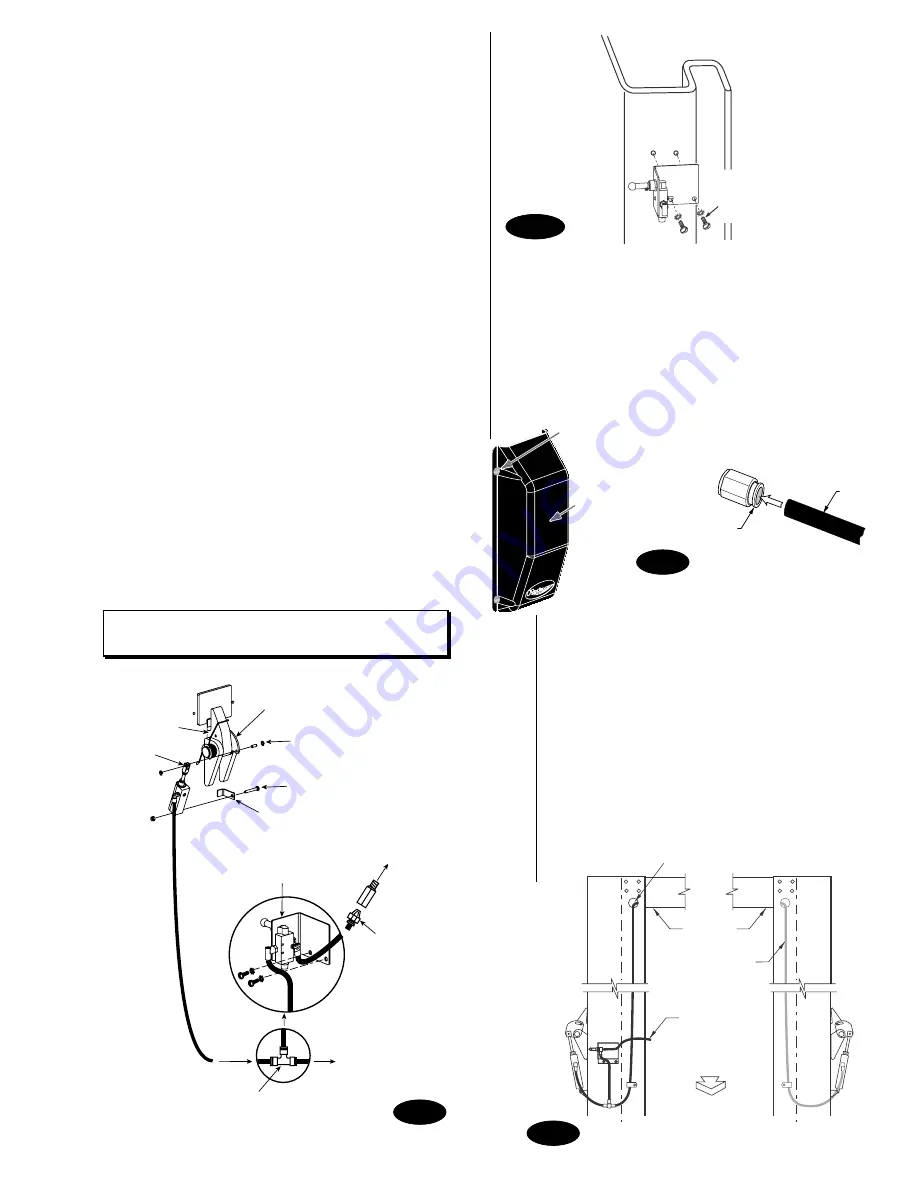

J)

Install air lines from main air supply (with filter) to

lowering valve. Install air line from lowering valve to

union tee then to the right column air cylinder.

K)

Install air line from union tee to left column air cylin-

der. Fig. 14.

L)

Mount lowering valve and bracket to column using

(2) 5/16"-18NC x 3/8" lg. PHMS, Fig. 12.

Note

:

Absence of air filter will void the warranty

on all pneumatic components

Fig. 12

Locking Latch Engagement Test:

A)

Raise carriages past the first latch position and

then lower onto latches.

B)

Check that the latches have fully engaged

when the release switch is not depressed.

C)

Raise carriages fully off latches. Now depress

release switch and check that the latches have

fully disengaged.

D)

Check for air leaks, make necessary adjust-

ments or repairs if required.

E)

Install latch covers with 5/16"-18NC x 3/8"

lg. BHCS, Fig. 13.

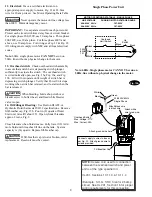

Note:

Cut provided tubing with sharp blade to length

as required. Tubing must be cut square with no burrs.

To assemble air line tubing into fitting, use firm, manual

pressure to push tubing into fitting until it

bot-

toms, see below. If removal of the air line tubing from

the fitting is ever required, hold Push Sleeve in (against

fitting) and at the same time, pull out on tubing.

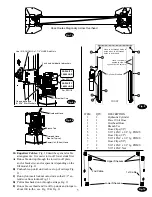

Fig. 14

Fig. 12b

5/16-18NC x 3/8" lg. BHCS

Latch Control

Cover

Air Line

Tubing

Push

Sleeve

* Do Not Route Switch Cord Thru This Hole

Overhead

Assy.

Air line comes out

on the front side of

lift on Left column

This line to

Main Air Supply

APPROACH

Rear View of Lift