BRP-Rotax

INSTALLATION MANUAL

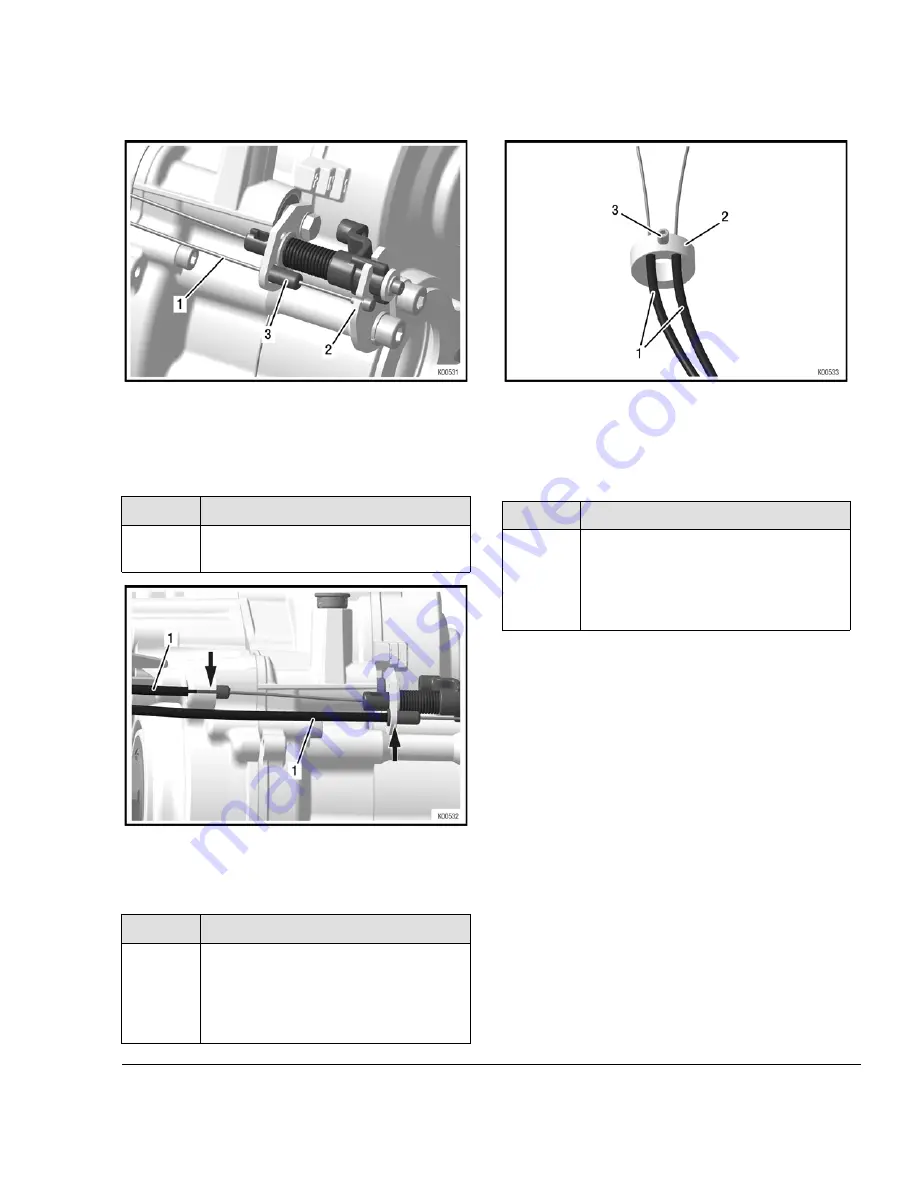

Figure 7.17

1

Bowden cable

2

Retaining plate

3

Guidance

Step

Procedure

9

Install Bowden cables (pos. 1) into the

support on the back of the engine.

Figure 7.18

1

Bowden cable

Step

Procedure

10

Thread both ends of the Bowden ca-

bles (pos. 1) through the cable support

(pos. 2). Install the set screw (pos. 3)

onto the cable support – just pre-as-

semble it, do not tighten yet.

Figure 7.19

1

Bowden cables

2

Cable support

3

Set screw

Step

Procedure

11

Hand-tighten both Bowden cables

(pos. 1) onto the control whip (pos. 2),

using M6. Allen screws (pos. 3) and

washers (pos. 4). Pay attention to the

correct installation of the control whip!

NOTE

The oblique millings (pos. 5) of the control whip

serve to guide the cables. The cable ends must

look away from the center of the control whip.

The Bowden cables can be attached to the control

whip in two different ways:

• Version 1:

Fasten Bowden cable to position 5 inside.

Feature: Shift travel longer, but less effort.

• Version 2

Fasten Bowden cable to position 5 outside.

Feature: Short shift, but higher effort.

Effectivity: 125 MAX DD2 evo

Page 9

Edition: September 01 2019

Summary of Contents for 125 MAX DD2 evo

Page 2: ...General information BRP Rotax recommends products of the following companies...

Page 63: ...Operator s Manual...

Page 65: ...Page 2 Edition September 01 2019 Effectivity 125 MAX DD2 evo NOTES BRP Rotax Operators Manual...

Page 67: ...Page 2 Edition September 01 2019 Effectivity 125 MAX DD2 evo NOTES BRP Rotax Operators Manual...

Page 73: ...Page 6 Edition September 01 2019 Effectivity 125 MAX DD2 evo NOTES BRP Rotax Operators Manual...

Page 81: ...Page 8 Edition September 01 2019 Effectivity 125 MAX DD2 evo NOTES BRP Rotax Operators Manual...

Page 113: ...Page 12 Edition September 01 2019 Effectivity 125 MAX DD2 evo NOTES BRP Rotax Operators Manual...

Page 119: ......