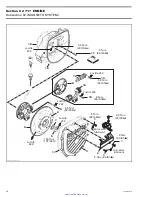

Section 01 ENGINE MEASUREMENT

Subsection 01 (MEASUREMENT PROCEDURES)

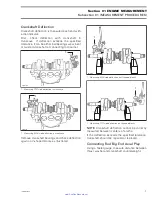

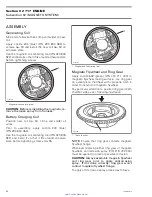

Crankshaft Deflection

Crankshaft deflection is measured each end with

a dial indicator.

First,

check

deflection

with

crankshaft

in

crankcase. If deflection exceeds the specified

tolerance, it can be either ball bearings wear, bent

or twisted crankshaft at connecting rod journal.

F01D1SA

1

1. Measuring PTO side deflection in crankcase

F01D1TA

1

1. Measuring MAG side deflection in crankcase

Remove crankshaft bearings and check deflection

again on V-shaped blocks as illustrated.

1

F01D97A

1. Measuring MAG side deflection on V-shaped blocks

F01D98A

1

1. Measuring PTO side deflection on V-shaped blocks

NOTE:

Crankshaft deflection cannot be correctly

measured between centers of a lathe.

If the deflection exceeds the specified tolerance,

crankshaft should be repaired or replaced.

Connecting Rod Big End Axial Play

Using a feeler gauge, measure distance between

thrust washer and crankshaft counterweight.

smr2005-085

7

www.SeaDooManuals.net