Section 02 717 ENGINE

Subsection 01 (LEAK TEST)

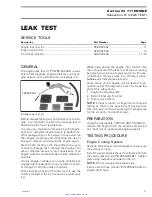

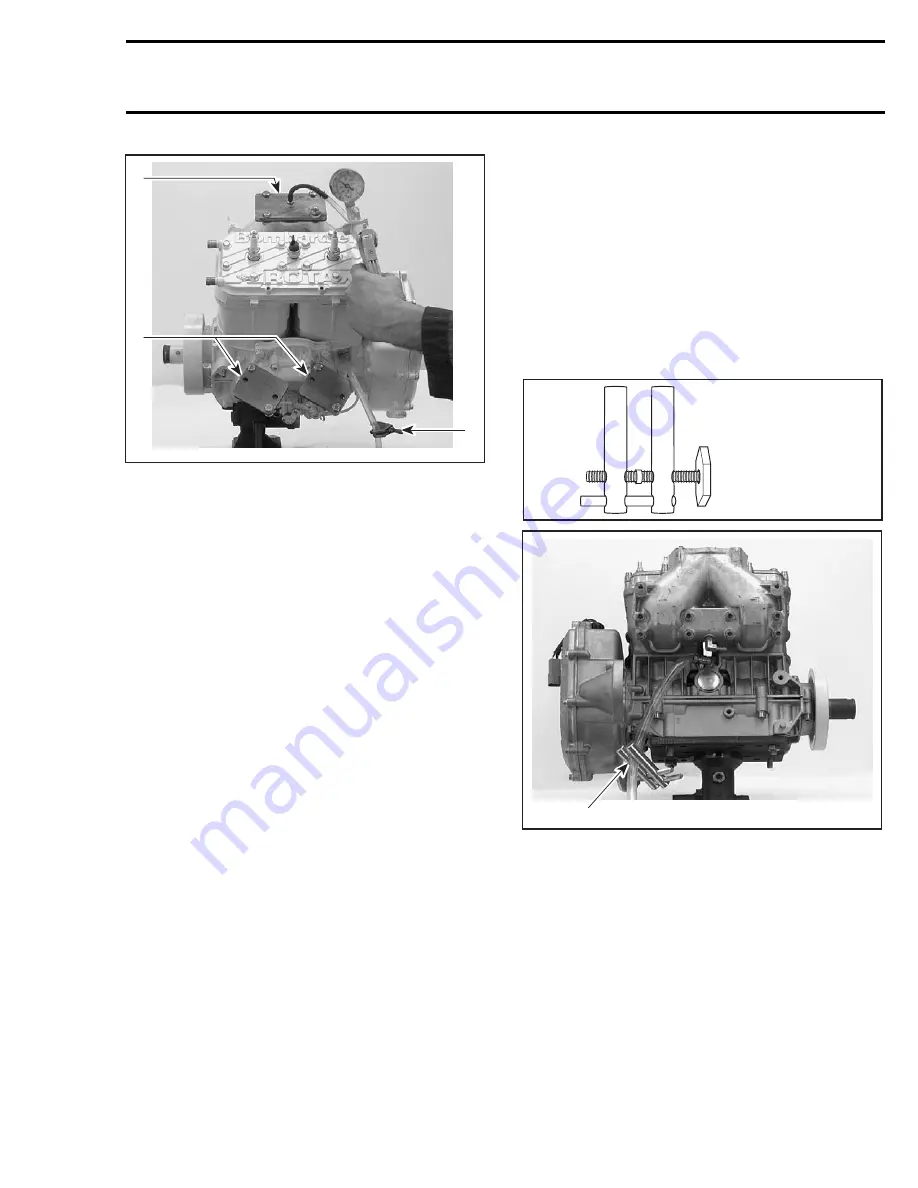

F01B2ZA

2

3

1

1. Intake plates

2. Pulse hose blocked with a hose pincher

3. Exhaust plate

Activate pump and pressurize engine to 34 kPa

(5 PSI).

CAUTION:

Do not exceed this pressure.

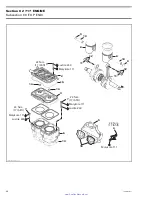

Wait 3 minutes and check if pressure drops; if so,

verify all testing components.

If kit components are not leaking, verify engine

jointed surfaces as per following areas:

– spark plugs

– cylinder head gasket

– cylinder base gasket

– crankcase halves

– rotary valve cover

– engine plugs

– exhaust manifold

– intake manifold

– oil injection pump.

Check also small oil injection pump lines and fit-

tings; check for air bubbles or oil column going

toward pump, which indicate a defective check

valve.

If the above mentioned components are not leak-

ing, block both oil hoses of the rotary valve shaft

using small hose pincher (P/N 295 000 076) on

each side.

NOTE:

If leakage stops at this point, proceed with

ROTARY VALVE SHAFT testing.

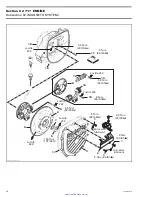

If there is still some leakage, remove the PTO fly-

wheel to verify outer seal.

If no leak is found on the PTO side outer seal,

remove magneto flywheel and verify crankshaft

outer seals.

Proceed with the ROTARY VALVE SHAFT testing

if the crankshaft outer seals are not leaking.

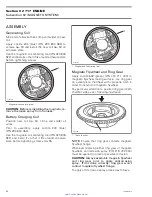

Rotary Valve Shaft

NOTE:

It is mandatory to drain the injection oil

from the rotary valve shaft.

Block oil return hose of the rotary valve shaft with

a large hose pincher (P/N 529 032 500).

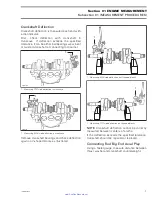

529 032 500

F01B31A

1

1. Oil return hose blocked with hose pincher

Install pump with reducer and nipple to the oil sup-

ply hose of the rotary valve shaft.

smr2005-075

13

www.SeaDooManuals.net