Section 02 717 ENGINE

Subsection 04 (BOTTOM END)

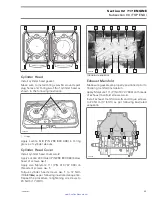

TOLERANCE

New parts

ENGINE

MEASUREMENT

Min

Max

Wear limit

MAG

N.A.

N.A.

0.050 mm

(.002 in)

Crankshaft

deflection

PTO

N.A.

N.A.

0.030 mm

(.001 in)

Connecting rod

big end axial play

0.311 mm

(.012 in)

0.677 mm

(.026 in)

1.2 mm

(.047 in)

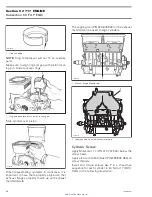

Crankcase

Inspect plane surfaces for warpage. Small defor-

mation can be corrected by grinding surface with

a fine sandpaper. Install sandpaper on a surface

plate and rub part against oiled sand paper.

Bearings

Inspect crankshaft bearings

no. 4

. Check for cor-

rosion, scoring, pitting, chipping or other evidence

of wear. Make sure plastic cage is not melted.

Rotate and make sure they turn smoothly.

ASSEMBLY

Assembly is essentially the reverse of disassem-

bly procedures. However pay particular attention

to the following.

NOTE:

It is recommended to spray injection oil on

all moving parts when reassembling the engine.

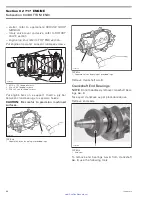

Crankshaft End Bearings

Heat up the bearing(s) using the bearing heater

(P/N 529 035 969). This will expand bearings and

ease installation.

A32CB7A

TYPICAL

CAUTION:

Bearing should not be heated to

more than 80°C (176°F). Do not heat bearing

with direct flame or heat gun or heated oil.

Inappropriate heating procedure(s) may cause

inner seal failure.

Turn bearing(s) several times during heating

process for heating it (them) properly.

NOTE:

Normally it takes approximately 10 min-

utes to heat up a bearing so in the event of replac-

ing bearing, it's recommended to start the bearing

heating process prior to removal operation. Two

bearings can be heated at the same time on one

bearing heater.

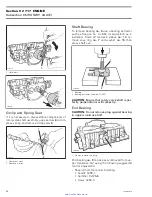

A32CB8A

1

TYPICAL

1. Bearings

smr2005-078

43

www.SeaDooManuals.net