Section 02 717 ENGINE

Subsection 03 (TOP END)

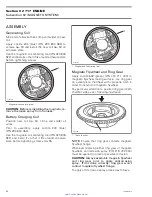

A01B1TA

1

1. Slide this edge

NOTE:

Ring compressor will not fit on oversize

parts.

Make sure to align ring end gap with piston locat-

ing pin. Slide tool over rings.

F01D0ZA

1

1. Ring end gap aligned with piston locating pin

Slide cylinder over piston.

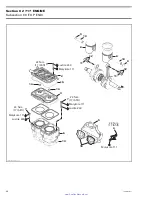

F01D10A

When reassembling cylinders to crankcase, it is

important to have them properly aligned so that

exhaust flanges properly match up with exhaust

manifold

no. 5

.

The aligning tool (P/N 420 876 904) or the exhaust

manifold can be used to align cylinders.

F01D44A

1

1. Exhaust flange aligning tool

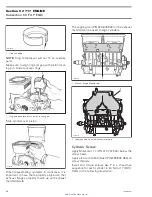

F01D45A

1

1. Aligning cylinders using exhaust manifold

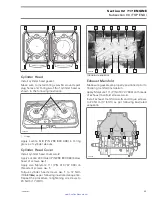

Cylinder Screw

Apply Molykote 111 (P/N 413 707 000) below the

screw head.

Apply also Loctite 243 (blue) (P/N 293 800 060) on

screw threads.

Install and torque screws

no. 7

in a criss-cross

sequence for each cylinder to 24 N•m (17 lbf•ft).

Refer to the following illustration.

34

smr2005-077

www.SeaDooManuals.net