BRP-Rotax

INSTALLATION MANUAL

INSTALLATION NOTES

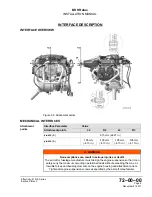

General

The representation of components in this chapter which are not scope of the delivery is

only symbolic. The design shown in this chapter does not represent a specified execution

but should support the understanding of the system.

The final design, the selection and specification of parts according to the respective appli-

cable regulations, the consideration of the system limitations and interface description as

well as the comprehension of the operating limits in every operational state is in the re-

sponsibility of the aircraft manufacturer.

The aircraft manufacturer has to make sure that the operating limits given in the Operators

Manual can be supervised by the pilot. The execution of the installation must allow the op-

eration of the engine according to the Operators Manual.

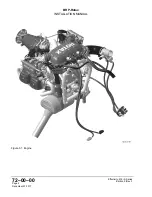

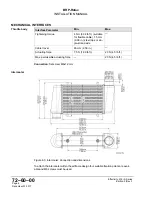

ENGINE SUSPENSION

ATTENTION

During engine installation take into account the total engine weight and ensure

careful handling.

The rubber mounts for neutralizing vibrations and other engine suspension components

are not in the scope of delivery. Those components must be designed, selected and

tested on vibration behavior during ground runs and flight testing at specified loads.

ATTENTION

The engine suspension must be designed to prevent excessive engine move-

ment and to minimise noise emission and vibration on the airframe.

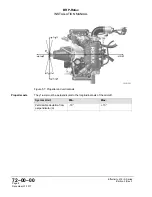

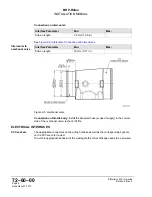

The engine suspension is determined essentially by the aircraft design. Four attachment

points are provided on the engine suspension frame assy.

The engine will be supplied with a well tried and certified suspension frame for attachment

on the fire proof bulk head. The exhaust system and the turbo charger are supported on

this frame, too. The installation into the aircraft is as generally practised by captive rubber

mounts which ensure also to balance out vibrations and sound from engine to aircraft

frame.

Effectivity: 915 i A Series

Edition 0/Rev. 0

Page 11

December 01 2017

Summary of Contents for 915 iS 3 A

Page 165: ......