11

EN

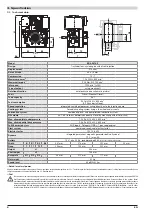

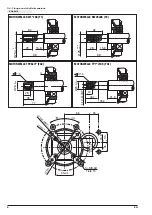

4.7. Concluding mechanical installation instructions

After the first start-up the correct alignment is to be checked while the

motor is as warm as it usually is while operating..

• All screws, nuts and other clamped or bolted connections must be correctly

assembled and fastened.

• The cooling air must be able to circulate without a problem.

The engines are equipped with a mechanical, adjustable speed regu-

lator. Make sure the injection pipe cannot vibrate with the engine at

any time, particularly when using the device at different speeds. This

could severely damage the injection pipes already after a short period

of time. If necessary support the injection pipes at appropriate spots..

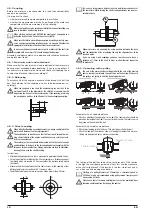

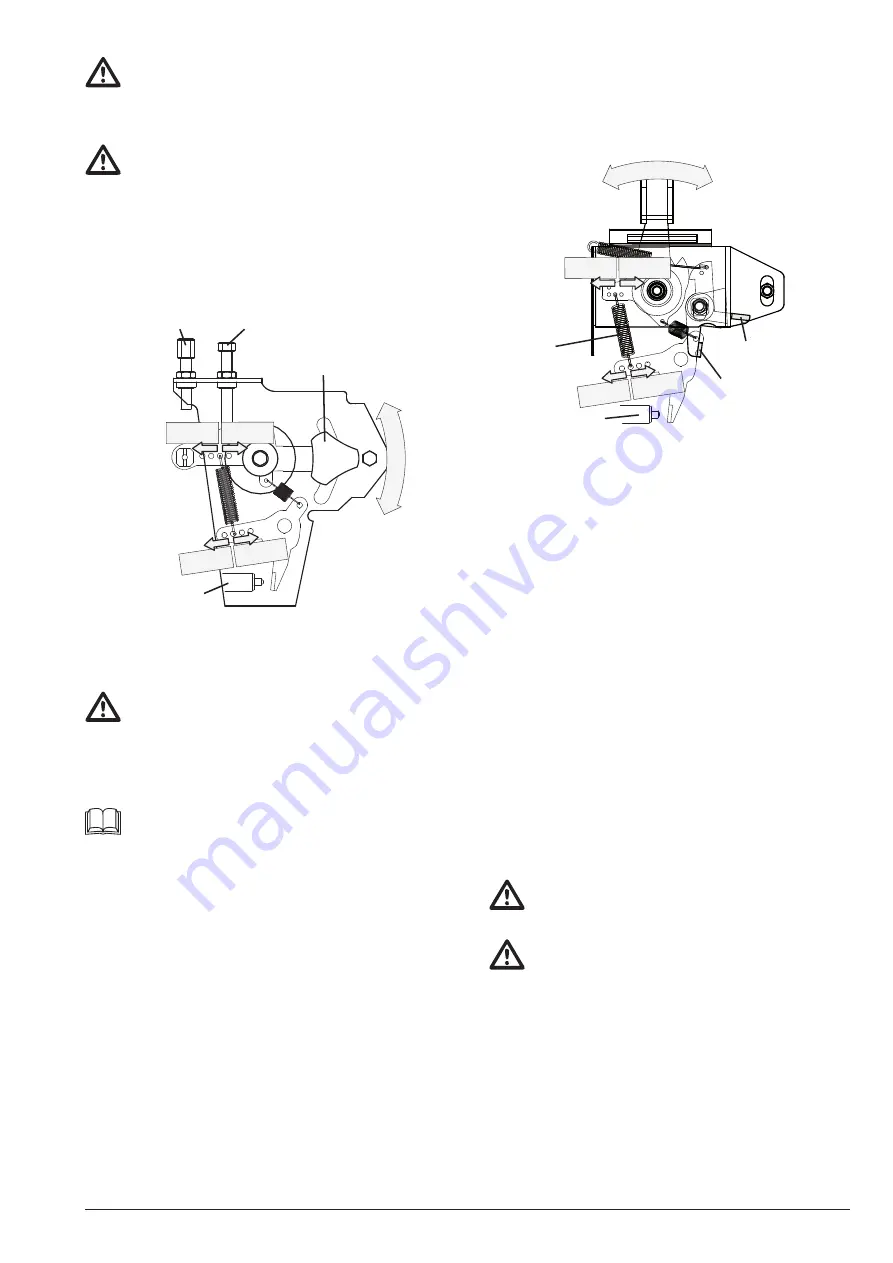

4.8. Speed controller

4.8.1. Type “A” – for variable speed

At delivery the engine is set up as follows:

➽

Maximal speed: 3.000 min

-1

➽

Idle speed: 1.300 min

-1

less

oscillate

faster

regulation

higher

speed

lower

speed

for wire rope

Adjusting screw max. speed

Adjusting screw

max. Injection qty.

Speed adjusting knob

Fasten to hold speed

Idle

Full speed

• If necessary attach a appropriate wire rope for speed regulation. There is a

clamp located at the left end of the governor. Here the rope should be attached.

• If an outher maximum speed than 3.000 min-1 is necessary in your applica-

tion, you can adjust the regulation-spring in different positions. Highest allo-

wed speed is 3.700 min

-1

If you change the set-up for the maximum speed, you also have to

readjust the adjusting screw for the maximum injection quantity.

Open the check-nut and adjust the screw as follows:

Load the engine with the nominal load according to the perfor-

mance curve and adjust the screw so that the engine achieves a

Bosch count below 4. Make sure to refasten the check-nut after

the adjustments.

If the engine is used above 1.000m sea level, readjustments of the

maximum injection quantity are also necessary.

4.8.2. Type “C” – for constant speed

This speed controller is made for fixed speed and is usually used

as a speed controller for generators. At delivery the engine is set up

as follows:

➽

Rated speed: 3.000 min

-1

If you want to change the engine speed, the regulating-spring must

be exchanged.

wire rope slot for

cut-off solenoid

Regulating

spring

Adjusting screw

max. Injection quantity

Bring lever in right position

„click“

cut-off lever

press to stop engine

Engine off

Rated speed

less

oscillate

faster

regulation

higher

speed

lower

speed

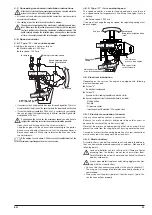

4.9. Electrical installation

Depending on the version the engine is equipped with following

electrical components:

➽

Version "H":

No electrical components

➽

Version "E":

Dynamo, Battery loading regulator and electric starter

➽

Special components (not included, additionally available):

- Starting battery

- Key box

- Oil pressure sensor

- Injection pump with mounted 12V magnetic valve

4.9.1. Electrical connection (chords)

Only use stranded wire cable as a connection.

B) as well as battery(-) chords are to be held as short as

because the current of the starter is very high.

Note that the motor and add-on-parts get hot when used. Always

protect the cable from touching hot parts by using a protective hose.

Caused by motor vibration during operation all screw connections

must be secured with spring washers or lock-nuts.

4.9.2. Starter battery

A starter battery and a battery cable are not included in the delivery,

they can however be ordered separately as add-ons. Make note of

following points:

Lead acid batteries contain sulfuric acid. If there are liquids

escaping from the battery, do not touch or swallow them.

Carefully dilate the acid with water and neutralize it with soda

(sodium carbonate).

Always wear protective gloves and safety goggles when wor-

king with the starter battery.

• You can find the necessary capacities in the chart in chapter 3.1.

The usage of valve-regulated (maintenance free) batteries is re-

commended..

• Always connect the plus(+) pole first, then the minus(-) pole. Fas-

ten the connections properly.