20

FA ROTEX A1 BGe - 02/2014

4

x

Set-up and installation

4.8.4 Connect the additional electrical components

When using a hot water storage tank you must connect a 3-way

diverter valve (a) or a storage tank charging pump (b) to the

switching field board. For this:

a) connect the connection cable of the 3-way diverter valve,

included in the scope of supply of the connecting kit A1

(

VSA1,

15 48 22

) or

b) the adapter cable for the connection of a storage tank charg-

ing pump (

E 1500430

)

the PCB plug

J2

(see fig. 4-13).

Additional optional regulating system components (room con-

trollers, mixer modules etc.) are connected to the switching field

via the PCB plug

J13

.

Additional switching contacts can be connected to the PCB plug

J8

for external boiler control.

4.9 Connect the gas line, check the burner

setting for gas type

4.9.1 Important instructions for gas connection

Gas connection

– Carry out gas connection conforming to the technical rules for

gas installation as well as the relevant specifications of the

country of destination and the gas supply company.

– A thermally triggered blocking device (TAE) and a gas flow

monitor (GSW) with a DVGW inspection symbol must be fit-

ted. The TAE must comply with the test basis of DVGW-

VP 301. The dimensions of the GSW must comply with the

maximum adjustable rated load of the device.

Gas type

– The gas burner has been factory-set for the gas type "natural

gas".

– Observe permitted gas inlet pressure (rest pressure)

(see tab. 12-3).

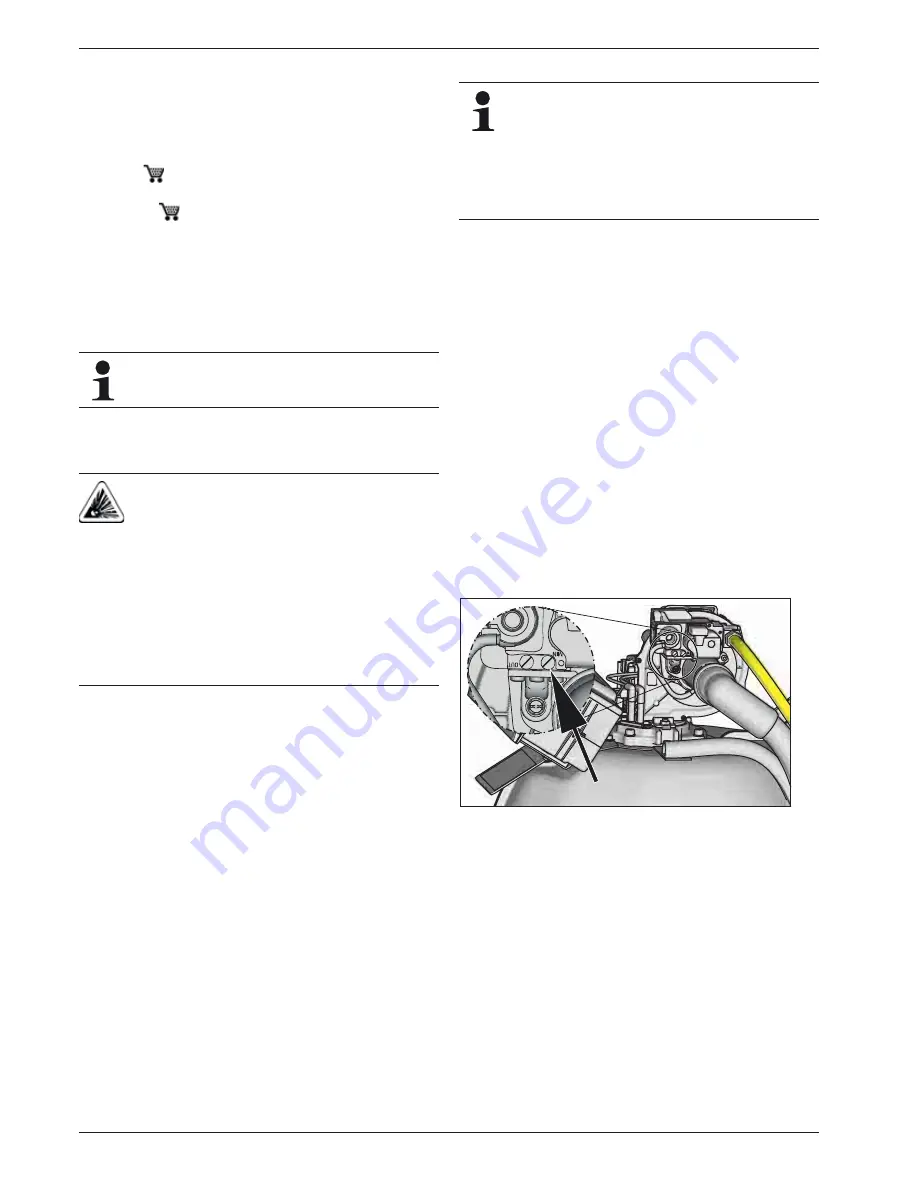

4.9.2 Connecting the gas line

Ɣ

Position the gas intake in such a way that the ROTEX A1 can

be opened without tension or restriction.

Ɣ

Connect the factory-mounted gas connection corrugated

hose (fig. 4-10, Item 3) (pipe thread EN 2999 Rp ½") to the

gas line without tension.

4.9.3 Checking burner pre-setting

Ɣ

Compare the available gas type with the set gas type (sticker

on burner housing).

The two gas types must match. If the burner is not labelled for

the available gas type, convert the burner to the new gas type

and label it (see chapter 7.3 "Burner setting").

Ɣ

Check the gas inlet pressure.

– If the gas inlet pressure is not within the permissible range

(see tab. 12-3), inform the responsible gas supply com-

pany.

– For liquid gas: Check the pressure reducer or adjust the

burner to the permissible gas inlet pressure

(see chapter 7 "Gas burner"). This adaptation must be

appropriately labelled with a suitable burner settings

sticker and an entry on the settings type plate (fig. 3-1,

item 23).

Additional information and a detailed description can be

found in the documentation "ROTEX Regulator RoCon

BF". It is included in the A1 scope of supply.

DANGER OF EXPLOSION!

Escaping gas is a direct threat to human health and

safety. Even a few sparks can cause very serious ex-

plosions.

Ɣ

Before working on gas carrying parts, always close

the main domestic gas stop valve.

Ɣ

If you can smell gas, ventilate the room thoroughly.

Prevent generating sparks or flames (e.g. from a

naked flame, an electrical switch or mobile phone).

Ɣ

Only heating specialists authorised and trained by

the gas or power supply company should be

allowed to work on gas-conducting parts.

The gas connection corrugated hose is dimensioned in

such a way that the ROTEX A1 can be opened up-

wards. The burner can thus be removed for mainte-

nance without having to disconnect it from the gas con-

nection.

The standard corrugated gas connection hose can

cause a pressure drop of up to 5 mbar. This will not

hinder operation of the ROTEX A1.

Fig. 4-14 Check the gas inlet pressure