48

FA ROTEX A1 BGe - 02/2014

9

x

Service and maintenance

Ɣ

Only on A1 BG 40(F)-e:

Ɣ

Remove the cylindrical burner chamber.

Ɣ

Remove the lower combustion chamber inset using the

combustion chamber wrench (fig. 9-14).

Cleaning the combustion chamber

Requirement:

The gap between the bottom combustion chamber half and the

sound deadening shell in the joint area is covered to prevent res-

idues from the upper combustion chamber half from falling into

the gap.

Special tool:

Cleaning brush and scraper fixed on the inside of

the boiler panels (included in the supply).

Remove dry residue (mostly in the upper combustion chamber

half):

Ɣ

Loosen the dirt and soot on the combustion chamber ribs by

using the cleaning brush and cleaning scraper.

Ɣ

Suction off the loosened dirt and soot by using a vacuum

cleaner.

Hard residues may arise in the transition region between dry and

water combustion chamber surfaces (usually in the lower half

shell of the boiler). These can only be removed by wet cleaning.

For this:

Ɣ

Loosen the dirt and soot under running water by using the

cleaning brush and cleaning scraper.

Ɣ

Rinse off loosened dirt with clean water into the drain.

Alternatively

, any residue can be removed with a high-pressure

cleaner.

For this:

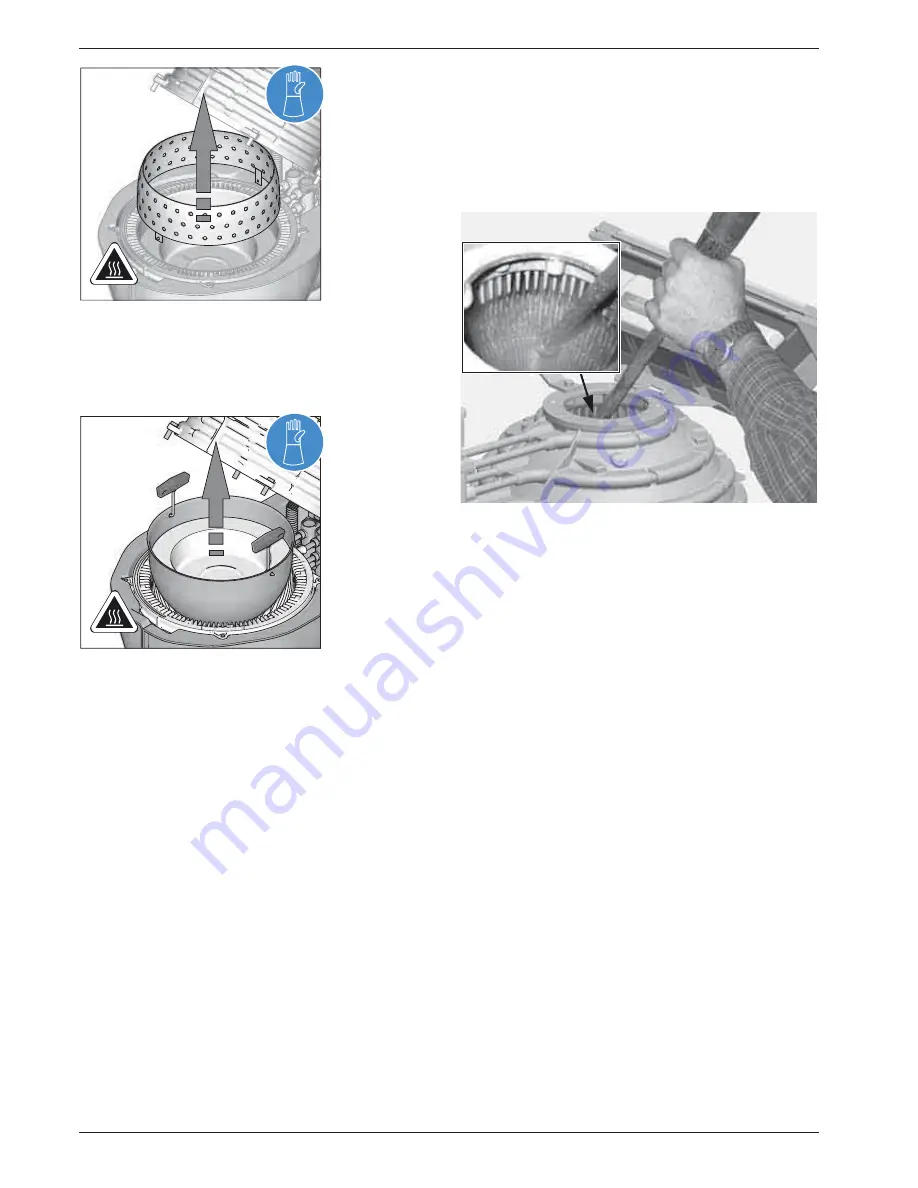

Ɣ

Close combustion chamber without combustion chamber

insert.

Ɣ

Unscrew burner and burner flange (see chapter 7.4

"Removing/fitting the burner").

Ɣ

Clean combustion chamber through burner flange opening

with high pressure cleaner (fig. 9-15).

Closing the combustion chamber

The combustion chamber is closed again in reverse order to

"Opening the combustion chamber".

The following must be observed:

– Replace the combustion chamber inserts completely if they

were removed for cleaning of the combustion chamber.

Only on A1 BG 40(F)-e:

– There must be no gap between the cylindrical and the lower

combustion chamber insert.

– When folding down the upper combustion chamber half you

must make sure that the upper (perforated) combustion

chamber ring does not tilt over.

– When

tightening

the four

allen bolts

,

start with the two

front bolts

.

Make sure that the upper combustion chamber does not tip

over and that it forms a tight seal.

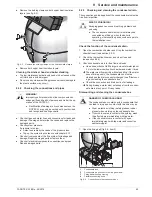

Fig. 9-13 Lift out the top burner chamber insert

(shown A1 BG 25-e)

Fig. 9-14 Lift out the bottom burner chamber insert

(shown A1 BG 25-e)

Fig. 9-15 Clean combustion chamber with high pressure cleaner