6

x

Faults and malfunctions

44

FA ROTEX Solaris RPS3 25M - 03/2010

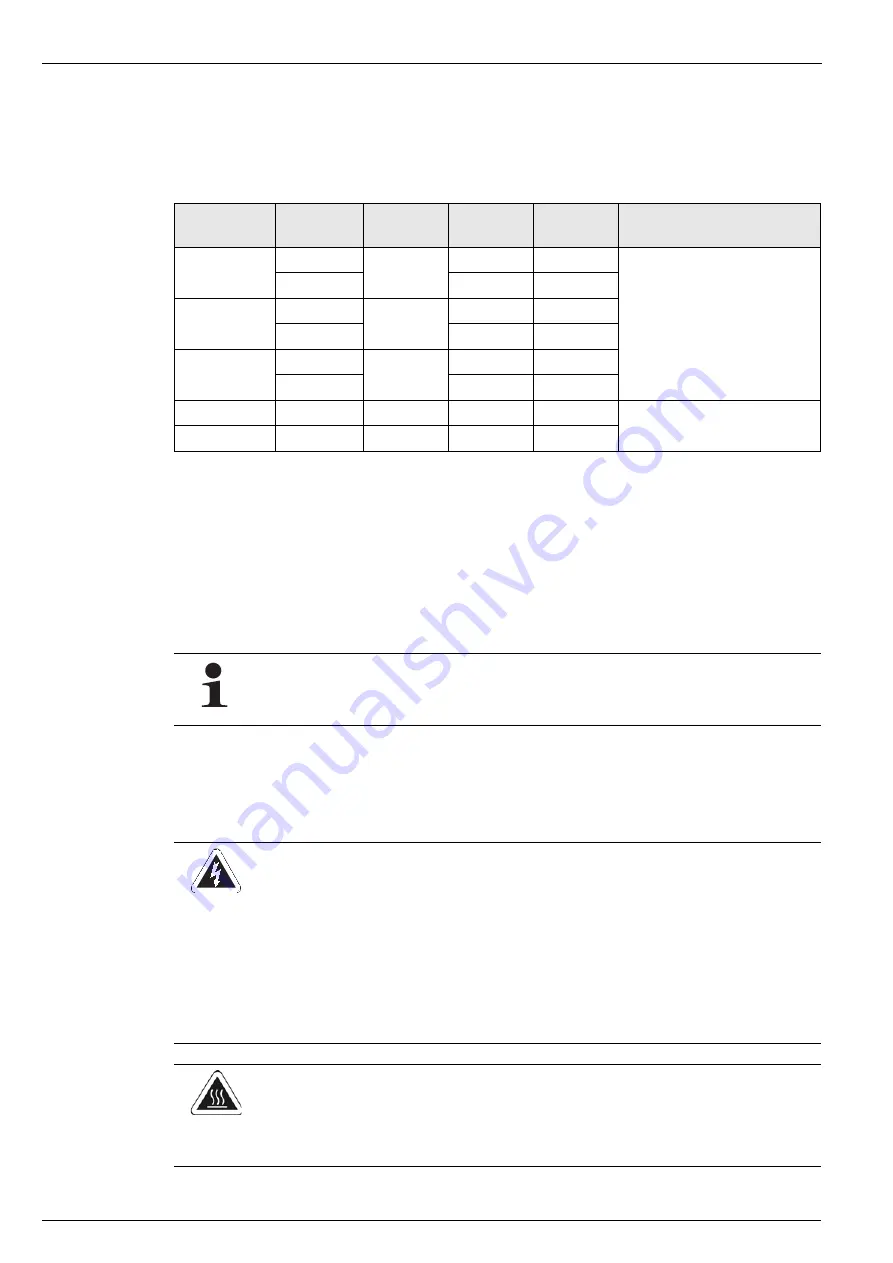

Sensor-specific error messages

With a break or short circuit in a sensor or sensor cable, the Solaris R3 control unit reacts as follows (see Table 6 -2):

– A flashing code letter in the status column indicates the fault, and an error message appears.

– The light associated with the sensor flashes.

– In addition, the control unit automatically intervenes in system operation.

All other sensor values remain accessible via the arrow keys.

Table 6 -2

Table of sensor faults

6.2

Troubleshooting

Operational events that are similar to faults

The temperature T

S

in the Solaris DHW storage tank reaches the value set under the "T

S

max" parameter:

– The circulation pump and, where installed, the booster pump, are switched off, the system runs empty. The T

S

light in the

Solaris R3 control unit flashes, the display shows the measured storage tank temperature. As soon as the storage tempera-

ture falls more than 2 K, normal system operation is resumed.

The temperature in the collector is higher than the switch-on inhibit temperature "T

K

perm"

– The circulation pump and, where installed, the booster pump, are switched off. The T

K

light in the Solaris R3 control unit

blinks. If the set switch-on inhibit temperature falls by more than 2 K, normal system operation is enabled automatically.

Faults

Sensor

Cause of the

fault

Status

(flashes)

Display

Light (flashes)

Consequence

Collector temp.

Interruption

K

uuuu

TK

Permanent switch-off

of P1 and optional P2

Short circuit

––––

TK

Return flow temp.

Interruption

R

uuuu

TR

Short circuit

––––

TR

Storage tank temp.

Interruption

S

uuuu

TS

Short circuit

––––

TS

Inflow temp.

Voltage drop

V

––––

no light

Operation without FlowSensor

FlowSensor

Voltage drop

D

––––

no light

In this case, short-term evaporation in the collectors is possible. The unpressurised steam escapes into the stor-

age tank. On rare occasions, small amounts of steam can escape from the Solaris DHW storage tank.

WARNING!

Live parts can cause an electric shock on contact and cause life-threatening burns and injuries.

•

To prevent hazards caused by damaged electrical cables, always have them replaced by a qualified

electrician in compliance with the applicable electrical guidelines and the regulations of the responsible

electricity supply company.

•

Repairs to damage on live components on the Control unit RPS3 25M may only be carried out by authorised

and approved heating engineers.

•

Before beginning repair work, Control unit RPS3 25M disconnect the from the power supply (remove fuse,

switch off main switch) and secure against unintentional restart.

•

Comply with the relevant safety at work regulations.

CAUTION!

Danger of burning on hot surfaces.

•

Let the unit cool down for a sufficiently long time before maintenance and inspection work.

•

Wear protective gloves.