Preparing for Operation

Installation

Your E-Z Cutter may be mounted on a bench or on

the E-Z Cutter Stand (#00037) which is available as an

accessory.

Bench Mounting: Ensure that the E-Z Cutter is

mounted on a bench sturdy enough to support the

E-Z Cutter's weight and the pressure generated by

normal cutting operation. The E-Z Cutter should be

bolted solidly to the bench with 1/2" diameter bolts.

Bolt the unit at the approximate location relative to

your pipe support system (see next pages).

E-Z Cutter Stand Mounting: Ensure that the E-Z Cutter

is bolted securely to the stand with 1/2" bolts and that

the machine is placed on a level area and bolted to

the floor with 1/2" studs after you have established

your pipe support system.

Power

Use proper electric current as shown on name plate.

To prevent power loss, extension cord of sufficient

capacity must be used.

To avoid electrical shocks when operating in the field,

connect the ground wire of the extension cord.

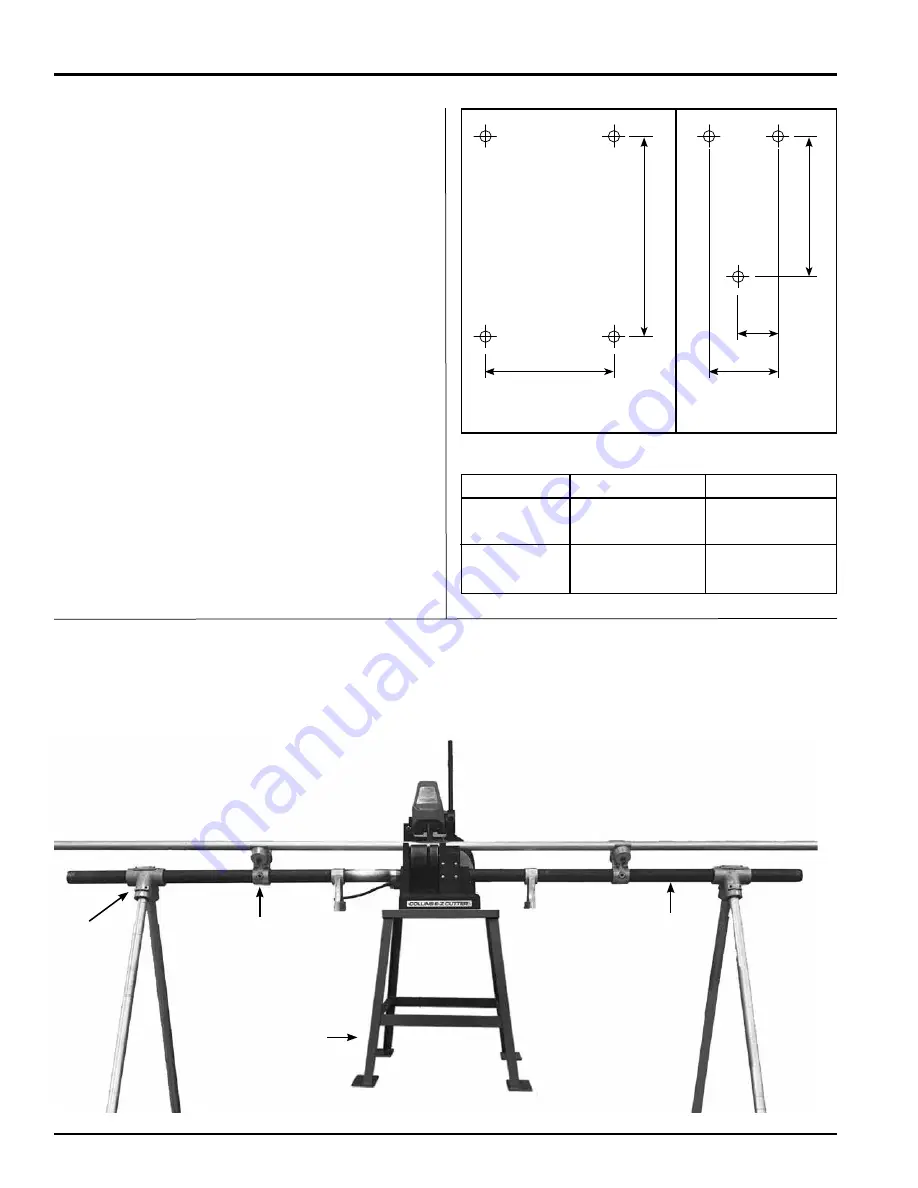

Installation of Your

Pipe Support System

Your E-Z Cutter combined with the appropriate

Collins accessories can put your company into

production cutting of pipe and tubing quickly.

16.0"

8.31"

4.91"

17

⁄

32

"

Diameter

Mounting

Holes

E-Z Cutter Stand

Hole Pattern

E-Z Cutter

Hole Pattern

29.0"

16.75"

Power

Cord Length

Wire Size

115 V

Below 50'

12-3

50'-100'

10-3

230 V

Below 50'

14-3

1 Phase

50'-100'

12-3

Pipe

Support

Fitting

E-Z Cutter

Stand

ROLLER

BEARING

SUPPORT

1

1

⁄

4

" Support

Pipe screws

into body of

E-Z Cutter

6

COLLINS E-Z CUTTER

Phone 800-545-7698 • FAX 815-633-0879

www.rothenberger-usa.com