Page 21

1355 - 1505 CYCLONE VERTICAL MIXER OPERATION

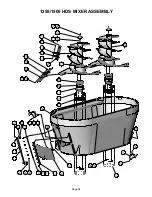

A trailer mounted tractor PTO driven feed mixer.

Pumps & Motors: Tandem Linde closed loop pumps driving 2 Poclain two speed motors. The mo-

tors turn the vertical augers used to mix cattle feed.

Operation feed back inputs: PTO pulse pick up, auger 1 and auger 2 motor speed pulse pickups,

and mixing pressure transducers.

Switch inputs: Low oil level, cooling fan on temp (120º), filter bypass, Warn Temp (180 º), Shut

Down Temp (200 º).

Keypad inputs: Mixing ON/OFF, Discharge ON/OFF, Display Screen UP, Display Screen DN,

Clean Out ON, Limp ON, and Warm (pressing Clean & Limp).

Calibration

Pressure transducers are calibrated in the code. No calibration is required.

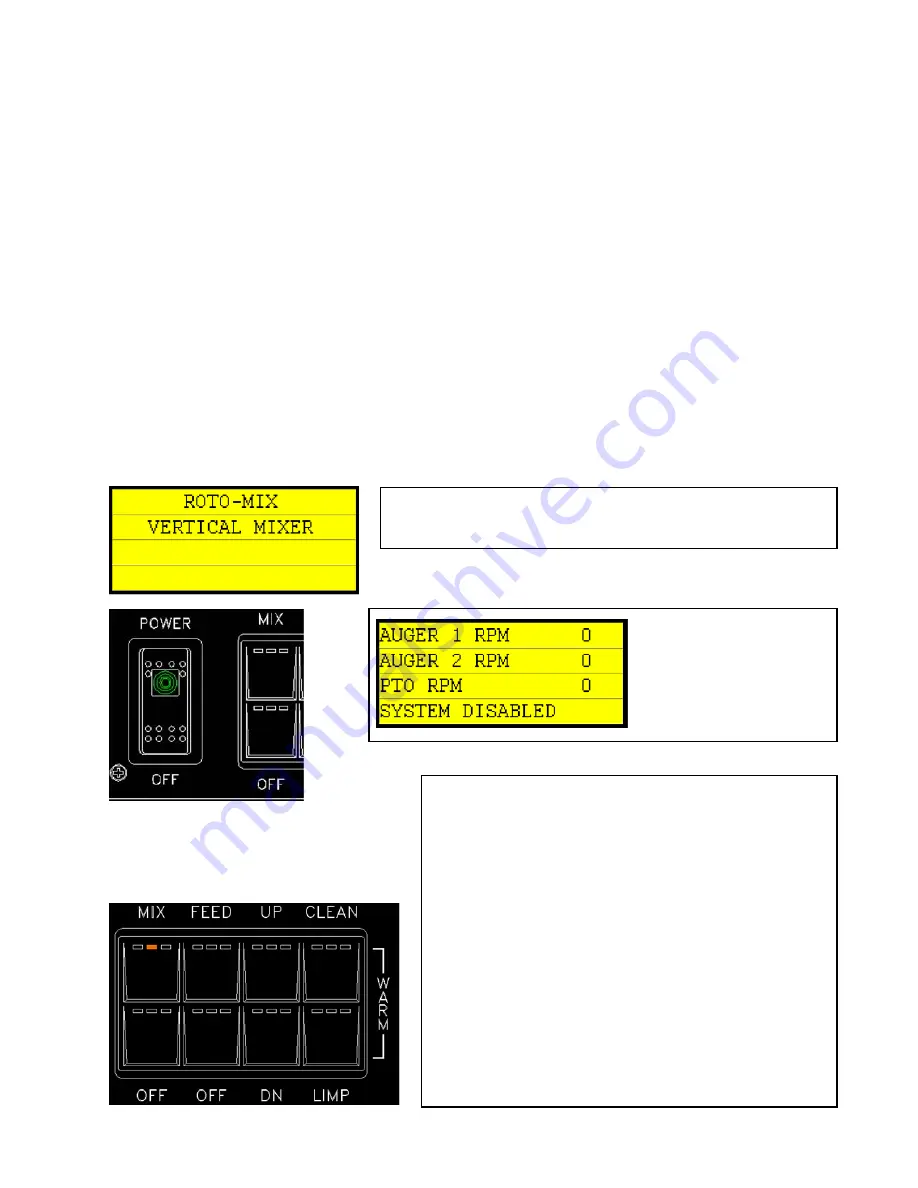

During power up this screen is on; after 5 seconds the

screen will switch to operation screen 1.

During power up this

screen is on; after 5

seconds the screen will

switch to operation

screen 1.

Key Pad Operation: (Momentary buttons)

To start mixing operation press MIX; to stop press OFF.

To start feed out operation press FEED; to stop press OFF.

To change display screen page use the UP or DN buttons.

Warm: Hold both Clean and Limp buttons to start warming mode

operation until the center LED’s blink. Release the buttons and

warm will stay on. Push either button momentarily to stop warm.

Clean Out: Push “Clean” button during feed operation at low

pressure (below 1500 psi) to start Clean Out.

Limp mode is used in emergency if a sensor is faulted or can be

used if there is not a fault. Hold Limp button until the three LED’s

stay on and release button. Push again to cancel limp.

Note: Shown with the Mix middle LED on during mix operation.

Starting operation and PTO speed :

I. Description of Operation :

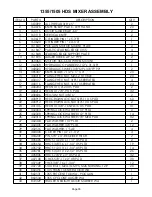

Summary of Contents for 1355 HDS

Page 2: ...Page 2...

Page 69: ......