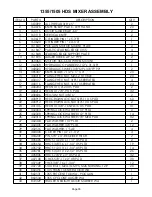

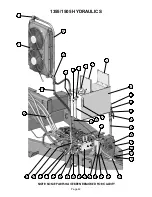

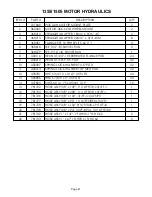

ITEM #

PART #

DESCRIPTION

QTY

1

161391

PTO SHIELD MOUNT BRACKET

1

2

161895

PUMP SUPPORT ARM LH

1

3

161896

PUMP SUPPORT ARM RH

1

4

161927

SELECTOR VALVE MOUNT PLATE

1

5

161928

DRIVELINE SHIELD

1

6

185302

P.T.O. SHIELD

1

7

310931SS PIPE PLUG, 1-1/2" SQ TOP SS

1

8

357400

BATTERY BOX W/STRAP

1

9

362060

LINDE TANDEM PUMP ASSEMBLY

1

10

362285

DOUBLE SELECTOR VALVE (CROSS W/HANDLE)

1

11

362555

SIGHT GAUGE 5"

1

12

368020

HYD SWIVEL 90º 3/8"MP x 3/8"FP

2

13

368028

HYD SWIVEL 90º 1/2"MP x 3/8"FP

1

14

368108

HYD ADAPTER STRAIGHT 3/8"MBPP x 3/8"FP

1

15

368116

HYD ADAPTER STRAIGHT 1/2" x 3/8" FP SWIVEL

1

16

372077

AXLE ASSEMBLY 77" WT

2

17

372188

TANDEM SUSPENSION KIT, 44000lb

1

18

374101

CAT 3 CLEVIS INSERT (PPI-208VR)

1

19

374109

BASE HITCH ( ISO-21244 ) (PPI-301VH) )

1

20

400107

HEX NUT, 3/8"-16 SERRATED FLANGE

8

21

400117

FLANGE HEX NUT 1"-8 SERRATED

2

22

400208

HEX NUT 1/2"-13 #5 PLTD

4

23

400210

HEX NUT 5/8"-11 #5 PLTD

2

24

400918

HEX CROWN LOCNUT 3/4"-10 #8 PLTD

1

25

401106

HEX NUT, 3/8"-16 NYLOC #5 PLTD

4

26

402005

SPRING LOCK WASHER 5/16" MED PLTD

4

27

402008

SPRING LOCK WASHER 1/2" PLTD

8

28

402009

SPRING LOCK WASHER, 9/16" MED PLTD

4

29

402010

SPRING LOCK WASHER 5/8" PLTD

2

30

402220

EXTERNAL STAR LOCK WASHER 10mm

1

31

402406

FLAT WASHER 3/8" PLTD

8

32

402505

FLAT WASHER 5/16" SAE

4

33

402510

FLAT WASHER 5/8" SAE PLTD

4

34

402512

FLAT WASHER 3/4" SAE

1

35

405653

HHCS 3/8"-16 x 1" #5 PLTD

8

36

405659

HHCS 3/8-16 x 2-1/2 #5 PLTD

2

37

405703

HHCS 1/2"-13 x 1-1/2" #5 PLTD

4

38

405754

HHCS 5/8"-11 x 2" #5 PLTD

2

39

405837

HHCS 1"-8 x 6" #5 PLTD

2

40

406488

HHCS 3/4"-10 x 5-1/2" #8 Pltd

1

41

407410

SHOULDER BOLT 3/8" x 3/8" LG x 5/16" THD

4

42

407804

HHCS 8mm x 16mm - 8.8 C.T.P.

4

43

407807

HHCS 14mm x 35mm - 8.8 C.T.P.

4

44

407808

HHCS 12mm x 35mm - 8.8 C.T.P.

4

45

407812

HHCS 10mm x 1.5 x 20mm PRP CLS 8.8

1

46

407824

HHCS 12mm-1.75 x 20mm GR 8.8

4

47

412020

PASSING LINK CHAIN 2/0 X 14 LINKS

1

48

440954

DECAL, USE SYNTHETIC 75W-90 ONLY

1

49

781235

RECAP TIRE & DUAL WHEEL 255R70 x 22.5

8

50

781527

HOSE ASSY 3/8" x 24-3/8", MP ENDS

2

51

860535

GEARBOX RESERVOIR WA

1

52

860536

1355 VERTICAL TRAILER WA

1

53

860551

SHIELD MOUNT ANGLE WA

1

54

860596

GEARBOX RR 2:1 WTIH PIPE CPLR

1

55

872090

DROP LEG JACK 9T

1

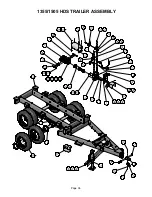

Page 37

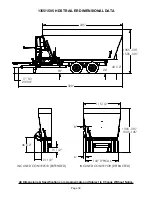

1355/1505 HDS TRAILER ASSEMBLY

Summary of Contents for 1355 HDS

Page 2: ...Page 2...

Page 69: ......