-7-

-6-

Operating Instructions

Disconnect the plug from the

power source before making

any assembly, adjustments or changing

accessories. Such preventive safety measures

reduce the risk of starting the tool accidentally.

Slide "ON/OFF" Switch

This tool is switched "ON" by the slide switch

located on the front of the motor housing.

TO TURN THE TOOL "ON" slide the switch

button up.

TO TURN THE TOOL "OFF" slide the switch

button down or "0" position.

Hold the tool with both hands

while starting, since torque of

the motor can cause the tool to twist.

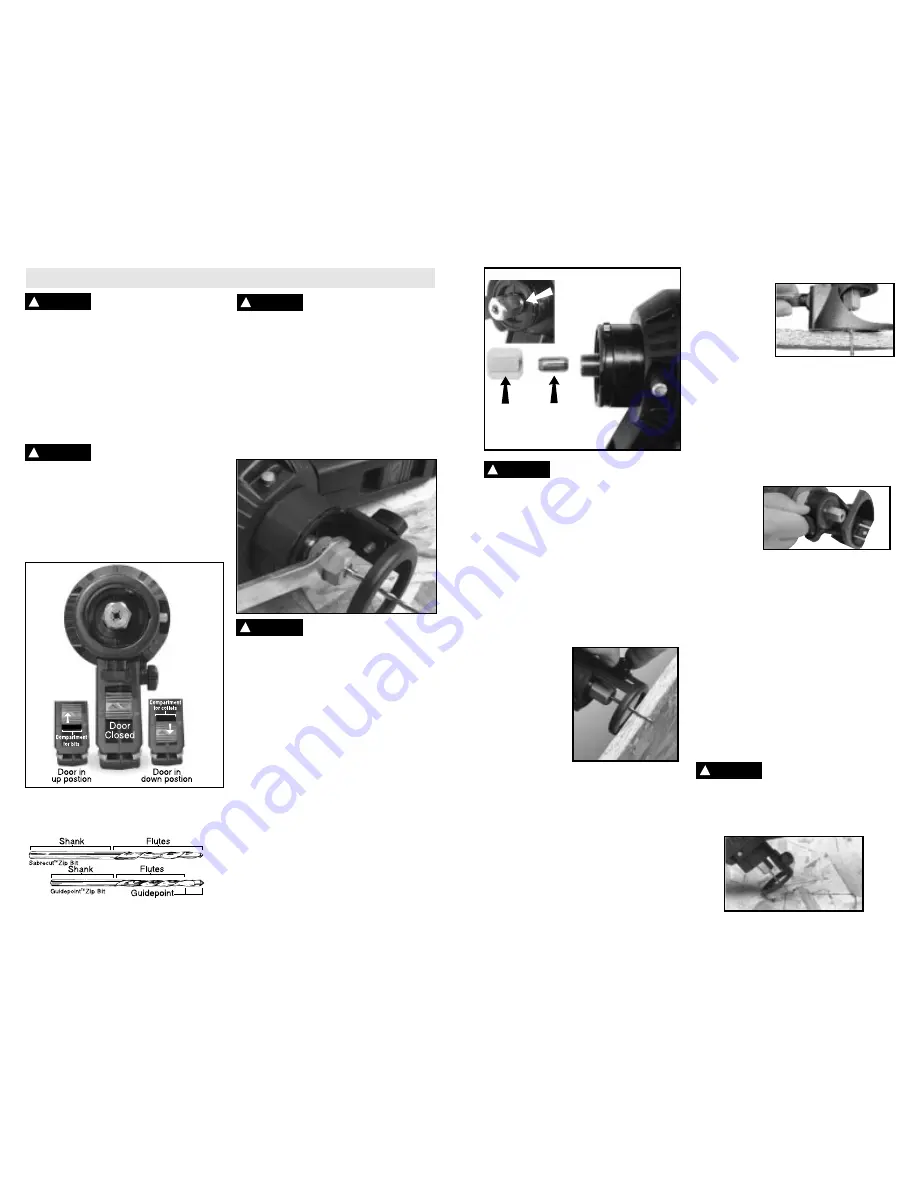

Installing Zip® Bits

The Zip Bits are held by a collet system. At the

time your tool was assembled, the 1/8" collet

(used for 1/8" Zip Bits) was installed for your

convenience. A 1/4" collet is required for

1/4” inch diameter Zip Bits, sold separately.

Do not use .118" shank bits in the 1/8" collet,

use only Roto Zip Tool Corporation 1/8" Zip Bits.

Identify the different parts of your Zip Bits.

The Zip Bit flutes are sharp

and should be handled with

caution.

Step 1:

To insert a Zip Bit into the tool, first remove the

standard equipment wrench and locate the shaft

lock button. Depress and hold down the shaft

lock button with one hand and at the same time

loosen the collet nut with the other hand by

turning it counter clockwise with the wrench for

a couple rotations.

Remove the old Zip Bit (if there is one), insert

shank of Zip Bit into the collet so that 1/16" to

1/8" of smooth shank remains visible above the

collet.

Do not allow the flutes/cutting

edges of the Zip Bit to fall into

the collet, and do not tighten the collet around

the flutes; doing so will result in broken Zip Bits.

After properly placing the bit into the collet,

depress the shaft lock button and

simultaneously tighten the collet nut in a

clockwise direction- first by hand and then with

the wrench until Zip Bit is held securely. Be

careful to not overtighten the collet nut when

using the wrench. Doing so will make the collet

hole smaller, preventing you from inserting Zip

Bits in the future.

Changing the collet

As stated above, the 1/8" collet is used with 1/8"

diameter Zip Bits and the 1/4" collet is used with

1/4" diameter Zip Bits. To interchange collets,

first remove the Zip Bit. Continue to loosen and

unscrew the collet nut until you can remove it

from the tool. Remove the collet and replace it

with another. (Each collet is double-ended, and

either end is acceptable to use.) By hand, re-

tighten the collet nut around the collet in a

clockwise direction. You are now ready to

insert a new Zip Bit as instructed in step 1

above.

!

WARNING

!

WARNING

DURING STORAGE of your

tool when there is no Zip Bit

in the collet, DO NOT tighten the collet nut

down onto an empty collet. Doing so will make

the collet hole smaller, preventing you from

inserting Zip Bits into it in the future.

Adjusting, removing and installing the

depth guide assembly.

(RTM01 & SCS01 models only)

Step 2:

Use the depth guide to adjust the depth of the

cut. The depth guide assembly consists of the

depth guide, locking knob and bracket. Loosen

(counter clockwise) the knob enough to enable

the depth guide to slide up or down to the

desired depth of your cut and re-tighten the

knob in a clockwise

direction. It’s best

to set the guide at

about 1/8" greater

than the material

thickness. For

example, to cut

1/2" plywood, set

the bit end so it

protrudes 5/8"

below the base

guide.

Note: Zip Bits can cut materials up to 1" thick.

In order to remove the depth guide, twist the

entire assembly, approximately 1/8 of a turn, in

a counter clockwise fashion. Pull the whole

assembly straight off the tool. To re-attach the

assembly, align the notched areas of the depth

guide bracket up to the indentations of the tool

collar. The depth guide assembly should easily

fall into place on top of the tool collar, and the

tops should be flush with one another. Twist

the assembly clockwise about 1/8 of a turn until

the spring locks in place.

Pro Series Classic Depth Guide assembly.

Locate the base

plate and its

locking screw.

Using the end of

the standard

wrench, loosen

( c o u n t e r

clockwise) the

screw enough to enable the base plate to slide

up or down to the desired depth of cut. For best

performance, set the base plate so the Zip Bit

protrudes approximately 1/8" beyond the

material being cut. For example, to cut a piece

of 1/2" thick plywood, set the base plate so the

Zip Bit protrudes 5/8" below the base plate, as

shown here. Re-tighten the screw in a

clockwise direction.

Removing Depth Guide Assembly From Tool

and Reinstalling

In order to

remove the

depth guide

from the tool,

release the

locking lever

and pull the

entire assembly straight off of the tool. To

reattach the assembly, fully replace the guide

onto the tool collar and lock the clamp lever.

Make A Few Practice Cuts

After assembling the Zip Bit into the tool and

adjusting your depth guide, as described above,

you should make a few practice cuts with the

tool before attempting an actual job.

A few exercises will give you the necessary

practice to make clean, professional cuts.

Step 3:

Make certain that the collet nut is securely

tightened before turning the tool on.

Step 4:

Hold the Spiral Saw power tool firmly and turn

the tool ON.

Hold the tool with both hands

while starting, since torque

from the motor can cause the tool to twist.

Step 5:

While holding the tool firmly, insert the bit into

the material at a 45° angle.

!

CAUTION

!

WARNING

!

WARNING

SYSTEM COMPLETE

COLLET

NUT

COLLET

SYSTEM SEPERATED

!

CAUTION