Subject to change.

Roto E-Tec DoorDrive

IMO_294_EN_v0

May 2013

25

Installation

Installation steps

16.

Join the two connectors to the control unit.

60

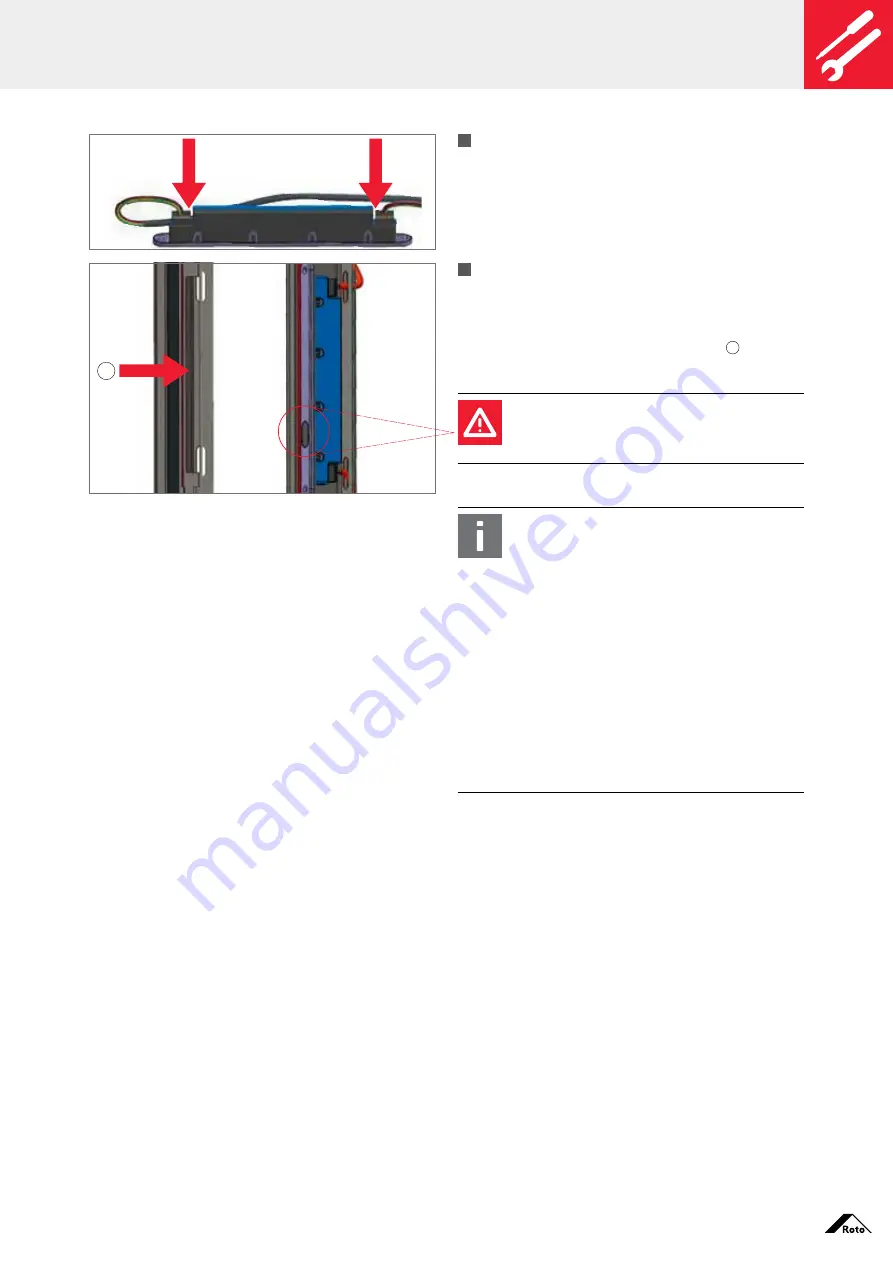

17.

Insert the electronic wiring for the door drive into the

designated milled recess in the door sash. When

doing so make sure that the cable is not kinked or

damaged.

Then, using the two self-drilling screws (

60

Page 18),

connect the door drive electronics to the door frame.

CAuTION!

The opening for programming the control

system must be down.

NOTE!

When installing the door, precautions have to

be taken to ensure that any unintended open-

ing over and beyond the maximum opening

angle is avoided – risk of damage to the swing

door drive!

– The maximum opening angle (< 105°) must

not be exceeded.

– The specified position of the retaining

bracket relative to the swing door drive must

be maintained. The coupling rod must not be

tensioned when it is installed.

– The specified wiring must be maintained

exactly as stipulated.

Summary of Contents for E-Tec DoorDrive

Page 51: ......