Subject to change.

Roto Safe E601 – Eneo AF

IMO_66_EN_v2 / 104674

.

August 2019

.

3

Installation and maintenance instructions

Maintenance instructions

The door manufacturer must draw

builders and end user’s particular at-

tention to these maintenance instruc-

tions.

In the event of non-compliance of this

advice, faultless system operation can-

not be warranted.

The following maintenance instruc-

tions shall be adhered to not less than

once a year – and also more often de-

pending on use:

The end user

must lubricate:

- Lubricate all movable parts and all

locking points of the locking system

must clean:

- The strikers may not be clogged up

or blocked.

- Use only cleaning and maintenance

agents that do not compromise the

corrosion protection of the hardware

components.

must check positioning and opera-

tion:

- Check movable parts on all locking

points for correct operation.

- Check that the lever-handle set is

mounted securely.

- Check that safety-relevant hardware

components are mounted securely.

- Examine safety-relevant hardware

components for wear and tear.

- Tighten fixing screws if necessary.

may not paint over:

- Do not paint over the lock (faceplate)

and/or the locking components.

shall notify a specialist if need be!

Only the specialist may:

Carry out work on the locking sys-

tem and respective hardware com-

ponents.

Replace components.

Replace fixing screws if necessary.

Testing the door

Check the system if it corresponds to

the list of original, approved supplied

components.

Check the door for prohibited retro-

fitted locking devices.

Test the emergency exit mode of

operation

Test the emergency exit mode of

operation at regular intervals.

Using a force gauge, measure the

operating forces that need to be

applied to release the emergency exit

lock, record this and compare it to the

clearance levels from the initial instal-

lation.

Installation instructions

Caution!

The emergency exit

lock is not suitable for use on

swing doors.

Avoid possible safety hazards when

using the emergency exit lock on

doors with stepped surfaces, e.

g. fin

-

gers or clothing getting trapped.

When using the emergency exit lock

on glazed doors, the glazed parts must

be made of safety glass or laminated

safety glass.

Emergency exit locks should be ap-

plied where the width of the escape

route is limited or the doors on which

the locking mechanisms are installed

can only be opened 90°.

The protrusion of the blocking ele-

ments may not impede the door’s free

movement.

Only the blocking mechanisms, strik-

ers and hardware, that were tested

together with the emergency exit lock

may used be.

Prior to installation:

– Ensure that the door has been pro-

duced and fitted correctly.

– Ensure that the door is not warped.

– Ensure that the door leaf and frame

run parallel to each along over the

entire height.

– Remove all impurities from the

routed area.

– Check the clearance – timber:

4 mm uniformly all round.

– Check the clearance – PVC:

12 mm uniformly all round.

– Check the clearance – aluminium:

uniformly all round in compliance

with the profile manufacturer’s spe-

cifications.

Installation

1. Crop the faceplate in line with the

door design.

2.

Screw fix the faceplate with Ø 4

mm

screws at right-angles to the face-

plate.

Use the appropriate fixing material for

fixing an emergency exit lock on tim

-

ber, PVC or metal doors.

Use through bolts for solid lever-

handle fixing.

Ensure that both the latch and all lock-

ing components close softly.

Profile gaskets may not hinder the

smooth

functioning of the emergency exit

locking mechanism.

When installing a door closer, bear in

mind that the door operation for chil-

dren, the elderly and the disabled is

not unnecessary hindered.

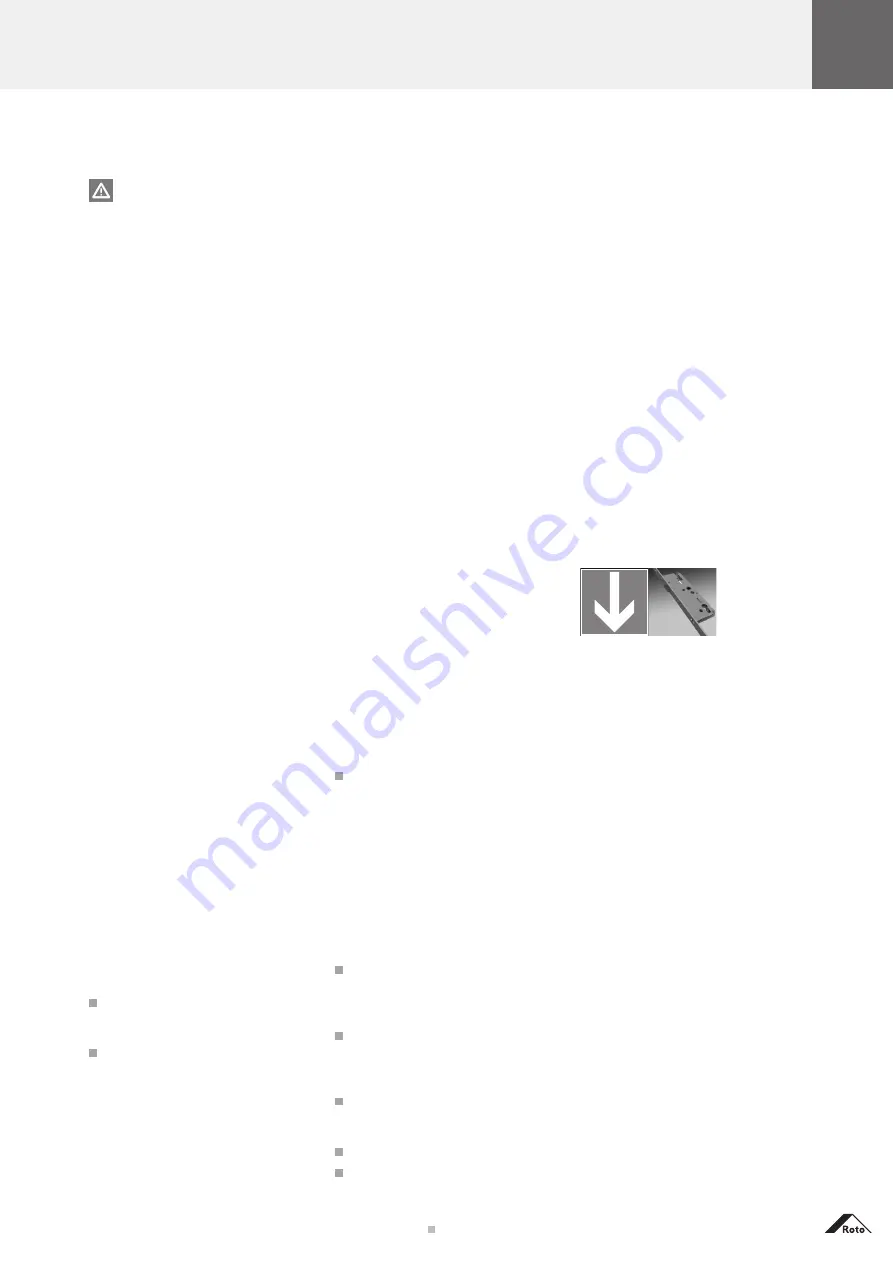

Marking

Attach the marking on the inside of the

door directly above the lever-handle:

either as a sign with the inscription

“Turn the handle to open” or a picto-

gram.

The pictogram should be min. 80 cm²

, and white on a green background.

Upon completing the installation of the

emergency exit lock, the arrow shall

point to the lever-handle.