Keeping the World Flowing

17

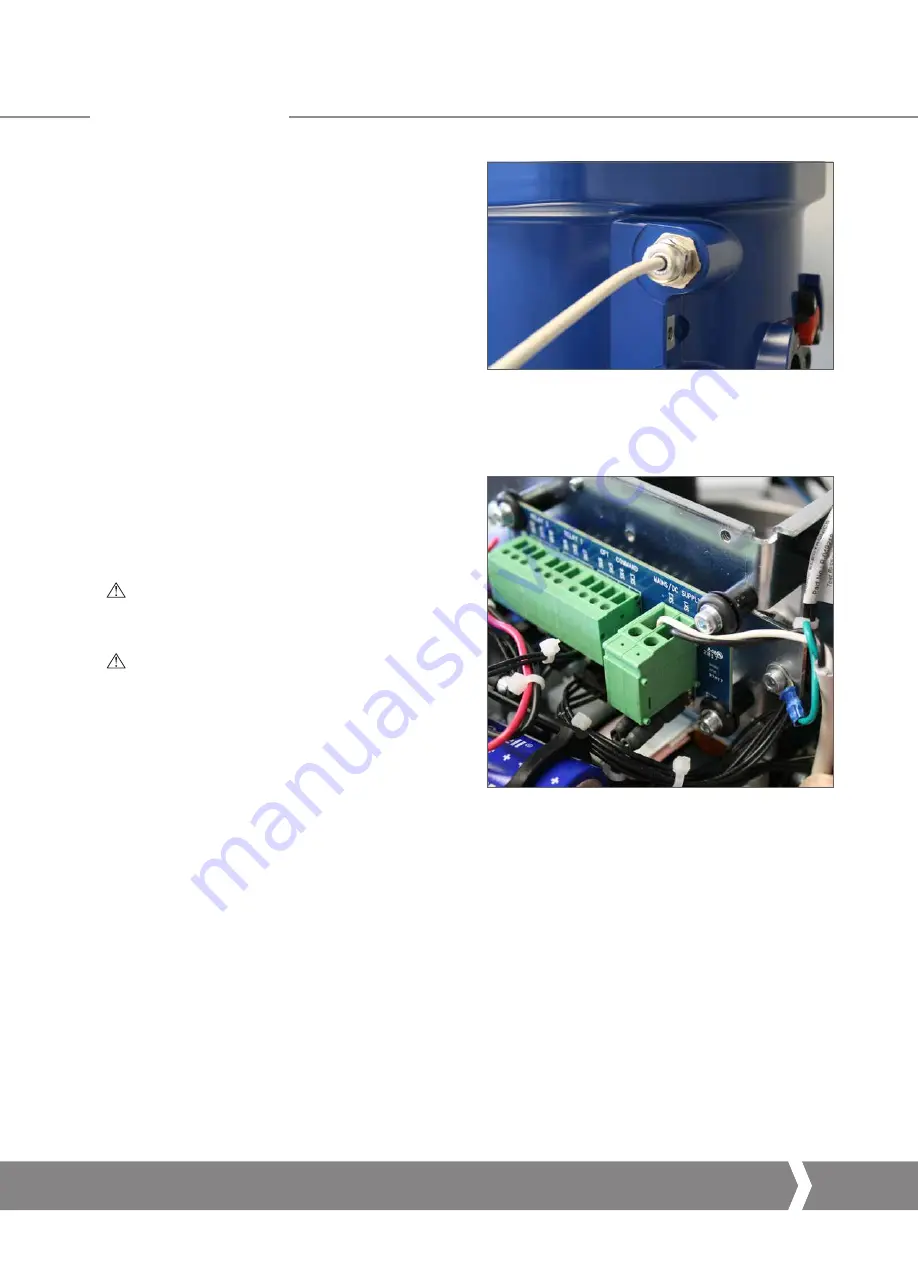

6.3 Electrical Installation

6.3.1 Cable Entries

The 4 cable entries are tapped either ¾” NPT or M25.

Remove any transit plugs. Make off cable entries appropriate

to the cable type and size. Ensure that threaded adaptors,

cable glands or conduit are tight and fully waterproof. Seal

unused cable entries with steel or brass threaded plugs.

If the actuator is to be installed in a hazardous area, a suitably

certified cable gland must be fitted with the use of a certified

thread adaptor where appropriate.

Unused entries must be closed with a suitably certified

blanking plug.

Wiring installation must comply with local statutory

regulations.

6.3.2 Connecting to Terminals

The wiring diagram supplied is particular to each actuator and

must not be interchanged with any other actuator. Check the

actuator nameplate to confirm wiring diagram number.

Refer to the wiring diagram to identify functions of terminals.

6.3.3 Cover Removal Precautions

WARNING

Carefully follow warning guidance provided in section

4.0 when removing the actuator top cover.

WARNING

Ensure all connected power supplies are isolated

before removing the actuator top cover.

Verify the supply voltage matches that stamped on the

actuator nameplate. A fused switch or circuit breaker must

be included in the wiring installation of the actuator. The

switch or circuit breaker must be installed as close as possible

to the actuator and shall be marked to indicate that it is the

disconnecting device for that particular actuator. Actuator

must be mounted such that it is not difficult to operate the

disconnecting device.

The actuator must be protected with an over current

protection device rated in accordance with PUB094-006

which details the electric motor performance data for CMA

range actuators.

Fig 6.8

Cable gland installation

Fig 6.9

Terminal block

6.0 Installation

A4

US

US

A4

US

A4

A4

US