-17-

SOFTWARE SETUP

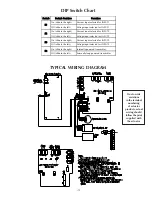

6.3 Output Relays

The actuator has three output relays that are configurable by

the user. They may be set to trigger on any one of thirteen

fault/alarm or actuator conditions. They may also be

configured as ENERG ON FLT or DEENERG ON FLT.

6.3.1 R1 ASSIGN

The Relay may be triggered upon any one of the following

conditions:

Fault

Process Variable Low

Local

Process Variable High

Remote

Set Point Deviation Low

Manual

Set Point Deviation High

Auto

Command Low

Stall

Valve Position High

Valve Position Low

When assigned to NONE, the relay will not trigger but is set

to the state that was set up by the R1 CONFIG parameter.

6.3.2 R1 CONFIG

The output relay may be configured as ENERG ON FLT

(energized on fault), relay closes on the fault condition or

DEENERG ON FLT (de-energized on fault) relay opens on

fault condition.

6.3.3 R2 ASSIGN

See Relay 1 Assignment, this operates in the same fashion

but on the second output relay.

6.3.4 R2 CONFIG

See Relay 1 Configuration, this operates in the same fashion

but on the second output relay.

6.3.5 R3 ASSIGN

See Relay 1 Assignment, this operates in the same fashion

but on the third output relay.

6.3.6 R4 CONFIG

See Relay 1 Configuration, this operates in the same fashion

but on the third output relay.

6.4 Contact Inputs

The actuator is equipped with two contact inputs that may

be configured by the operator.

6.4.1 INPUT SW ACTIVE

Setting this parameter to YES enables input Switch 1. When

active, the INPUT CONFIG and INPUT SW SET parameters

are also made accessible to the operator. If INPUT SW

ACTIVE is set to NO, no other Input switch 1 parameters are

accessible (not displayed) and switch 1 input is not used.

6.4.2 INPUT SW CONFIG

When Input switch 1 is enabled this parameter configures

whether the switch is normally open (NORM OPEN), action

is taken when the contact closes or normally closed (NORM

CLOSED), action is taken when the contact opens.

6.4.3 INPUT SW SET

The user has two options for actuator positioning when this

switch is activated. It may be set to either LOCK (lock in

place) or DRVIE TO ZERO (run to the ZERO position) .

6.4.4 ORIDE SW SET

Setting this parameter to YES enables the input standby

switch. When active, the Override Switch Configuration is

also made accessible to the operator. If the ORIDE SW SET is

set to NO, the Override Switch configuration parameter is

not accessible and the Override switch input is not used.

6.4.5 ORIDE SW CONFIG

When ORIDE SW SET is set to YES this configures whether

the switch is normally open (NORM OPEN), action is taken

when the contact closes or normally closed (NORM

CLOSED), action is taken when the contact opens.

When the override switch is activated the actuator will drive

to the ZERO position and the lower line of the display will

show OVERRIDE at all times.