-8-

General

The electrical installation, maintenance and use of these

actuators should be carried out in accordance with the

National Legislation and Statutory Provisions relating to the

safe use of this equipment, applicable to the site of installa-

tion.

For the UK: Electricity at Work Regulations 1989 and the

guidance given in the applicable edition of “IEEE Wiring

Regulations” should be applied. Also the user should be fully

aware of his duties under the Health and Safety act 1974.

For USA: NFPA70, National Electrical Code ® is applicable.

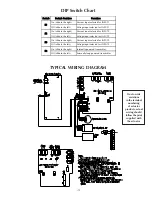

The basic wiring diagram is shown on page 9, however the

actual wiring must follow the print supplied with the actuator.

Input Power

Input power, (100-240VAC ±20%), terminates at TB1 on the

power supply board. Live and Neutral must be connected to

terminals 1 and 3 respectively. The power supply is auto-

sensing therefore no switch settings are required for selection

of input voltage range.

The incoming power supply earth ground must be securely

connected to the ground screw terminal located inside the

actuator base.

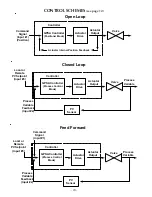

Command Wiring

The analog input signals are used for automatic positioning of

the actuator. The assignment of each channel is as follows:

Proportional: J3-1 (+ve) and J3-2 (-ve)

Process Variable: J3-3 (+ve) and J3-4 (-ve)

Remote Setpoint or Remote Ratio: J3-5 (+ve) and J3-6 (-ve)

Consult ‘Control Setup’ section of this document for more

information. The input signal may be configured for voltage

(1-5V) or current (4-20mA) and is achieved by use of dip

switches S1 – S3, see section titled ‘

Setting the Dip

Switches

’. Each analog input channel is fully isolated.

MECHANICAL SETUP

Relays

The GPSA provides 3 user configurable relays for position or

monitoring indication. The relays may be configured to

energize or de-energize on the assigned condition. The

contacts are rated at 10mA to 5A, 250V AC, 30V DC. The

relays will de-energize under loss of power.

The connections are as follows:

Relay 1: J1-7 Normally Closed

J1-8 Normally Open

J1-9 Common

Relay 2: J1-4 Normally Closed

J1-5 Normally Open

J1-6 Common

Relay 3: J1-1 Normally Closed

J1-2 Normally Open

J1-3 Common

Contact Inputs

The Contact Inputs provide an additional pair of isolated

inputs for specific control purposes, (see ‘

Start-up Informa-

tion

’ section of this document). These inputs are activated

by connecting the corresponding pair of terminals together.

Input SW should be wired to terminals J2-3 and J2-4. The

Stand-by switch is wired to J2-5 and J2-6. Information

regarding the configuration of these switches can be found in

the ‘

Start-up Information

’ section of this document.

Transmitter

A current loop transmitter provides a 4-20mA signal that

corresponds to the measured position. This may be either

loop powered or internally powered, (see the section titled

‘

Setting the Dip Switches

’). In the internally powered mode,

the feedback signal wires connect to terminals 2 (+ve) and 1

(-ve) of J2 respectively. In the loop powered mode however,

the signal wires connect to terminals 1 (+ve) and 2 (-ve) of

J2 respectively. The transmitter is fully isolated.

Setting the Dip Switches

There are four dip switches situated on the main logic PCB

that are used for actuator configuration. They are located

behind the display near the display board standoffs. Switches

S1 – S3 determine the type of command signal, (voltage or

current) used by the actuator, for analog inputs 1 – 3 respec-

tively. Switch S4 is used to select between a loop powered

and internally powered current transmitter. It should be

noted that the orientation of the transmitter’s terminals is

different for the two modes.