A4

US

US

A4

US

A4

US

A4

A4

US

US

A4

US

A4

A4

US

44

IQ3 Full Configuration Manual – Section: Data Log

Data logs, which are able to store vast amounts of operational

and environmental information, are provided as standard on the

IQ. Due to the nature of the graphical display, information can

be displayed locally at the actuator using the supplied Rotork

Bluetooth

®

Setting Tool Pro.

The stored information can be used to view, diagnose and trend

any type of operational condition that may affect the valve,

actuator or process. With asset management becoming preferred,

the data log helps to achieve goals set out by process conditions.

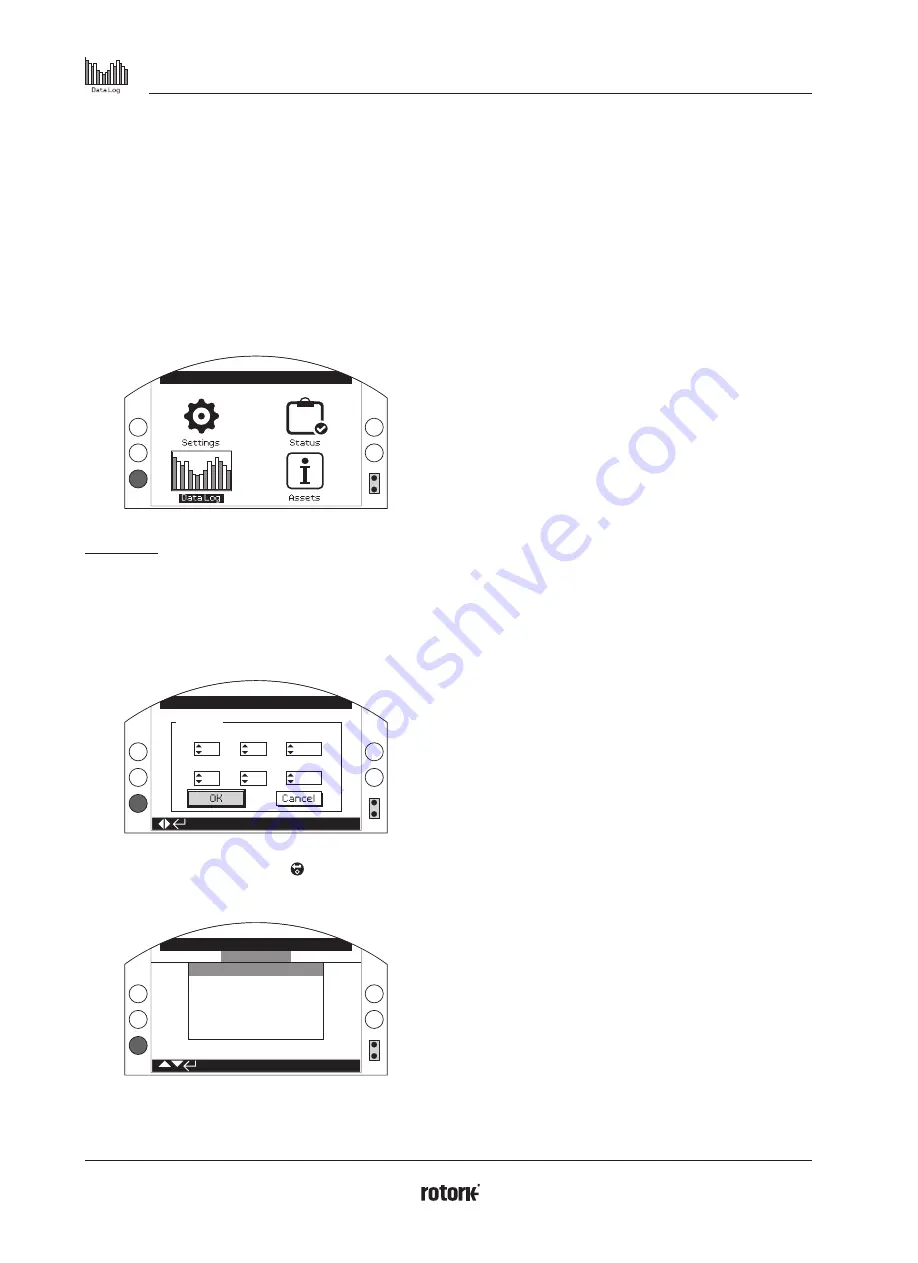

Refer to section 1.2 for connecting to the actuator. Once

connected, use the four directional arrows to navigate to the

main icon menu. From here you can highlight and select the Data

log icon:

Open Limit

Main Menu

The first time you enter the data log menu, you will be given the

opportunity to set the current time and date. This time and date

is ONLY for the local display and does not affect the dates when

you download the data log for viewing in Insight2. If you want

to set the current time and date, please refer to section 4.6 for

details.

Set Date

Open Limit

Hour

9

23

14

5

44

2013

Day

Minute

Month

Second

Year

Check the current time and press enter . You will now be

shown the main Data log menu below:

Stopped

Data log Menu

Torque Logs

Event Logs

Trend Logs

Operation Logs

Partial Stroke

Set Log Date

4. Data Log

4 Data Log menu structure

Page

4.1

Torque

Logs 45

4.1.1

Valve Torque Live

45

4.1.2

Valve Torque Profile

46

4.1.3 Valve Torque Reference

46

4.2

Event

Logs

47

4.2.1 Control Event Log

47

4.2.1-1 Event Log Filter

48

4.2.1-2 Control Event Log

50

4.2.2 Error Event Log

51

4.3

Trend

Logs

51

4.3.1

Temperature 52

4.3.2

Battery

52

4.3.3 Vibration Average

53

4.3.4

Vibration

Peak

53

4.4

Operation

Logs

54

4.4.1 Starts Profile

54

4.4.2

Statistics 55

4.4.3

Service

Log

56

4.4.4

Bluetooth

Log

57

4.5

Partial

Stroke

58

4.5.1 Partial Stroke Results

58

4.5.2 Partial Stroke Torque

59

4.6

Set Log Date

59

Summary of Contents for IQ Multi-Turn

Page 2: ...2...