Keeping the World Flowing

19

12.0 Operation

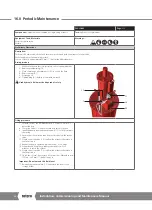

Single-acting actuator, type 1 and type 2,

cylinder stop bolt setting

Perform the following operations as first setting.

Adjust the stop bolt located in the end flange of the cylinder

as follows:

2

3

5

1

A. Verify the absence of pressure

B. Remove cap nut (5) and O-ring (2)

C. Loosen stop nut (1)

D. Slowly pressurize the cylinder to detach stop bolt

from piston

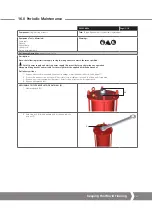

3

E. With the help of a suitable size wrench, rotate the stop

bolt (3) counter clockwise to increase the angular stoke

F. Remove the pressure

G. Verify the newly obtained angular position with one stroke

H. Repeat operations E to G, until the desired angle

is obtained

3

I. With the help of a suitable size wrench, rotate the stop

bolt (3) clockwise to decrease the angular stoke

J. Remove the pressure

K. Verify the newly obtained angular position with one stroke

L. Repeat operations I to L, until the desired angle is obtained

3

1

M. Hold the stop bolt (3) with a wrench and carefully tighten

the stop nut (1)

2

5

N. Re-position the O-ring (2) and verify it is correctly

positioned. Tighten cap nut (5)

A4

US

US

A4

US

A4

A4

US

Summary of Contents for LP/S Series

Page 89: ...Keeping the World Flowing 89...