30

Installation, Commissioning and Maintenance Manual

PM-LP-005

Page: 1/1

Component:

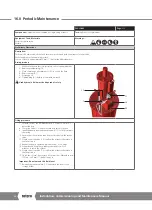

Hydraulic manual override for single-acting actuator

Task:

Hydraulic oil replacement

Equipment, Tools, Materials:

Project documentation

Wrench

Warnings:

Preliminary Operations:

Description:

Tasks must be executed with the tank in vertical position and with the actuator in fail position.

Verify the absence of pneumatic pressure.

Correct oil level is approximately 25 mm (1") below the fill/breather port.

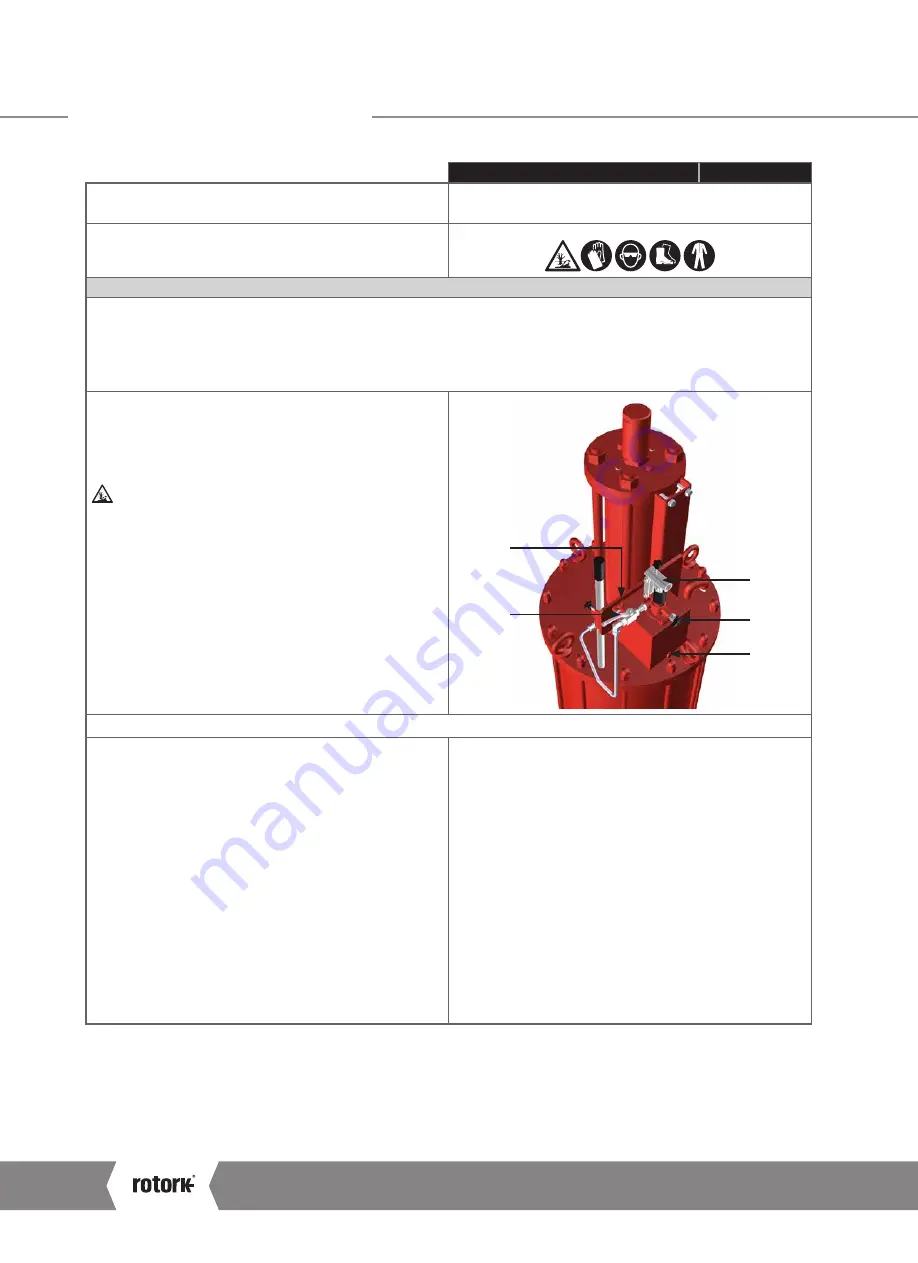

Drain procedure

1. Make sure the actuator is in fail safe position (spring released)

2. Remove breather/plug (1.5)

3. Place containers under drain port (D1) to collect the fluid

4. Remove plugs (D1)

5. Discharge oil

6. Tighten plug (D1) back in its seat with a wrench

Used hydraulic fluid must be disposed of safely.

1

1.5

1.1

1.2

D1

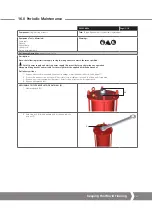

Filling procedure

7. Fill with oil from the fill /breather port (1.5) up to 25 mm (1")

below the port

8. Close stop valve (1.2) and verify that stop valve (3) is open

9. Install the pump lever and operate pump (1.1) to fully compress

the spring

10. Ensure the oil level in the tank does not drop below the intake

tube

11. Slowly open stop valve (1.2) to allow the actuator the return to

the fail position

12. Repeat the pump operation procedure from 2 to 3 times

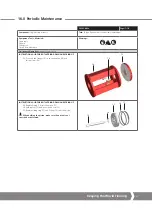

13. Pressurize and keep the cylinder pressurized from 3 to 5

minutes, to settle the oil level

14. Slowly open stop valve (1.2) to allow the actuator the return to

the fail position

15. Check the oil level. If necessary, fill in from the fill /breather port

(1.5) up to 25 mm (1") below the port

Important: Do not exceed this fluid level.

17. Reinstall the tank breather (1.5) and return the lever to the

storage holder

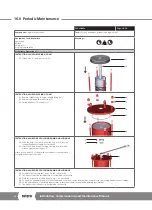

16.0 Periodic Maintenance

A4

US

US

A4

US

A4

US

A4

Summary of Contents for LP/S Series

Page 89: ...Keeping the World Flowing 89...