14

Installation, Commissioning and Maintenance Manual

12.0 Operation

Actuator LP/S Type 1 and 2

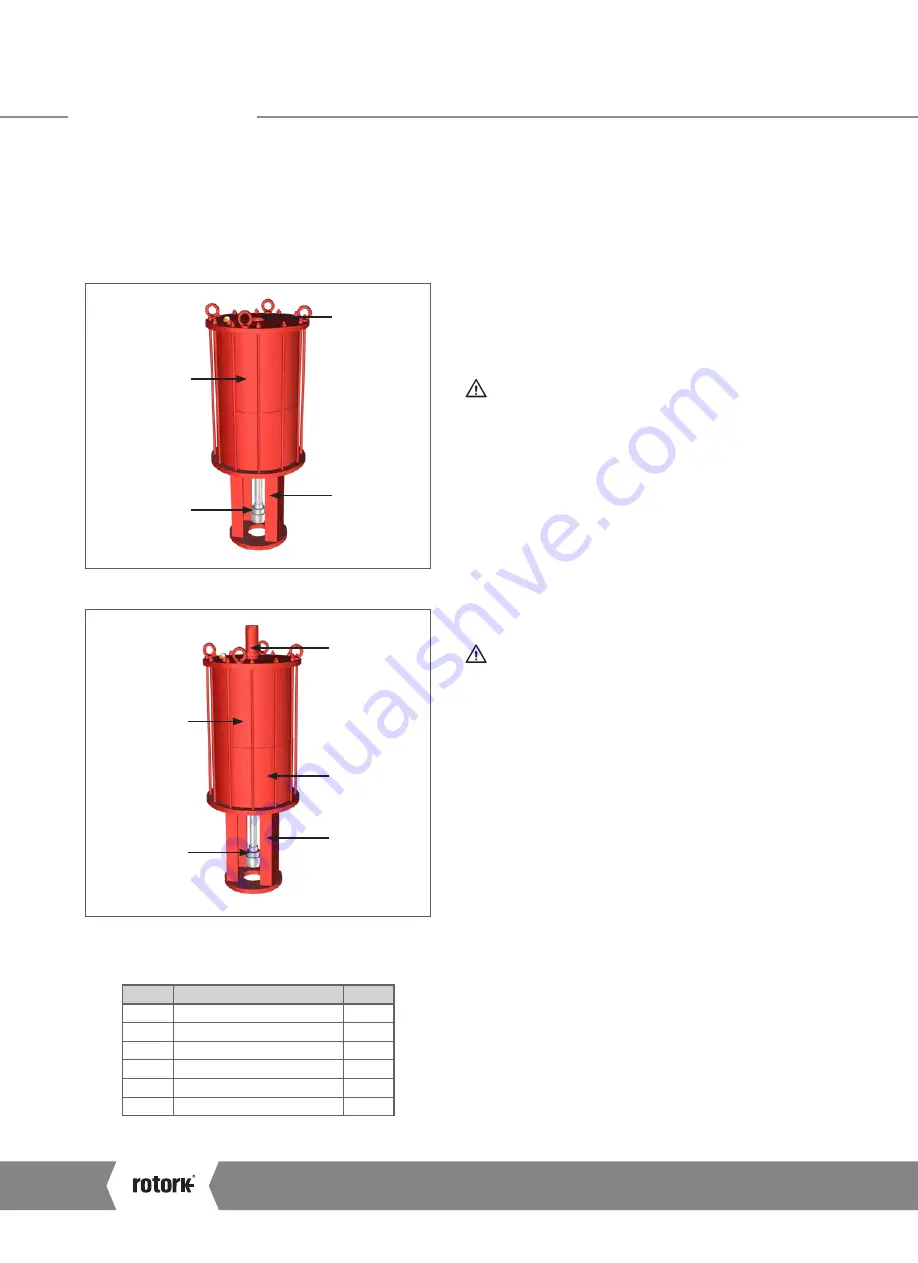

Main components of LP/S type 1 and type 2 actuator are

shown in Fig 12.3, Fig 12.4, Fig 12.5 and Fig 12.6.

Type 1 and type 2 differs in the spring package type installed,

but since the latter must not disassembled for safety reasons,

from a maintenance point of view can be regarded as identical.

1

4

5

2

Fig 12.3 LP/S type 1/type 2 without stop bolt main components

6

4

3

5

2

Fig 12.4 LP/S type 1/ type 2 with stop bolt main components

Table 2: LP/S type 1/type 2 Parts list

IT

DESCRIPTION

QTY

1

Plug

1

2

Spring cartridge

1

3

Cylinder tube

1

4

Spool piece

1

5

Valve connection

1

6

Stop bolt

1

12.3 Operating Description

Please refer to the Operating Diagram supplied for the

specific actuator.

12.4 Manual Override

The LP series can be fitted with an emergency manual

override suitable to operate the actuator in the event of fluid

supply failure.

This device can be of mechanical screw type operated by

means of a handwheel, or of hydraulic type, with a hydraulic

cylinder operated using a hydraulic hand pump.

A maximum operating time of the manual override

of 24 hours, for maintenance or testing,

is recommended.

Note: The use of manual override is not recommended

in SIL applications. If it is necessary, strictly follow

instructions reported in the following paragraphs.

Before operating the mechanical manual override, ensure

that the cylinder is not pressurized and that the actuator is in

the fail position, then proceed as indicated in the following

paragraphs.

Important:

It is recommended to regularly clean the

“M” jackscrew and grease it afterwards.

Use a Molykote HSC PLUS grease.

After each use, verify that the manual override has

been disengaged before returning to remote operation.

The manual override can be of mechanical type or

hydraulic type.

A4

US

US

A4

US

A4

US

A4

Summary of Contents for LP/S Series

Page 89: ...Keeping the World Flowing 89...