Keeping the World Flowing

25

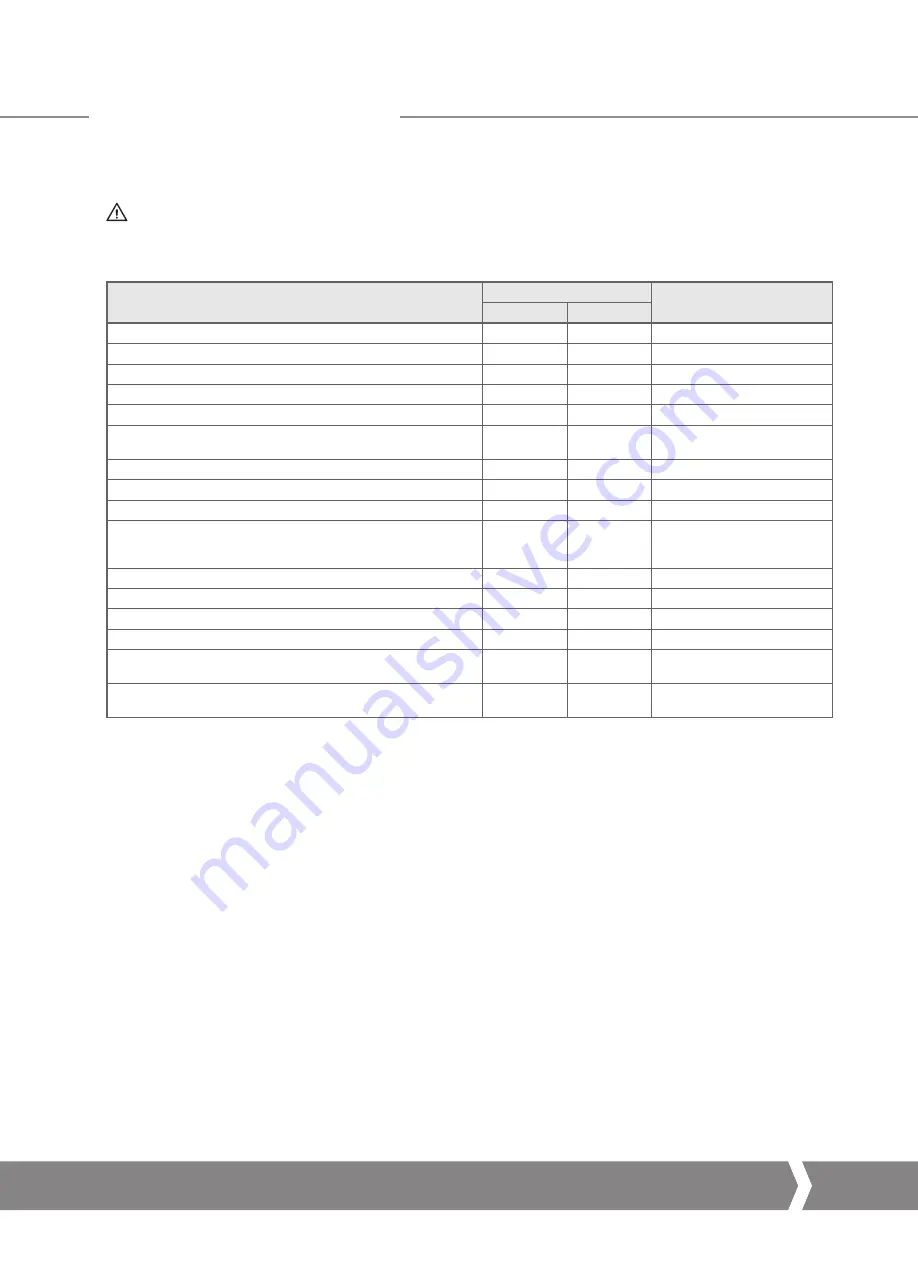

16.0 Periodic Maintenance

Rotork recommends performing the following checks to help comply with the rules and regulations

of the country of final installation:

Remove pressure before proceeding with maintenance operations, discharge any accumulators

or tanks (if present), except where otherwise indicated.

Periodic Maintenance Schedule

MAINTENANCE ACTIVITY

PERIODICITY

REFERENCE

Months

Years

Visual check of external components and control groups

6*

*

Verify welding. In case of anomalies contact RFS

6*

*

Breather cleaning

6*

*

Check pneumatic connections for leaks. Tighten pipe fittings as required

-

1*

Cleaning

-

1*

Visual check of painting. Verify absence of damages. Repair if necessary

according to painting specification

-

1*

Functional test

-

1*

Functional test by manual override

-

1*

Check electrical components (if present) and grounding connections

-

1*

Check threaded connections (bolts, studs and nuts) with valve. If necessary

tighten to the recommended torque, in accordance with the size and the

characteristics of the fastener material installed by the customer

1*

Single-acting actuator hand pump oil replacement (if present)

-

5*

Pneumatic cylinder seals replacement type 0

-

5*

Pneumatic cylinder seals replacement type 1 and type 2

-

5*

Hydraulic cylinder for manual override seals replacement

-

5*

Manual handwheel MH and MHD seals replacement –

LP/SD and LP/SU actuator, cylinder up to size 235

-

5*

Manual handwheel MH and MHD seals replacement –

LP/SD and LP/SU actuator, from size 235 to 385

-

5*

(*) The time between maintenance tasks will vary depending on the medium and service conditions. Refer to End User Plant Preventive Maintenance

Program for specific task frequency.

For Functional Safety applications refer to Safety Manual.

Specific maintenance could be necessary for specific application.

Refer to job documentation for eventual additional maintenance tasks.

A4

US

US

A4

US

A4

A4

US

Summary of Contents for LP/S Series

Page 89: ...Keeping the World Flowing 89...