RS-485 Data Highway, Connections and MFU Setup

Publication PUB091-003-00_0119

17 of 76

4 RS-485 DATA HIGHWAY, CONNECTIONS AND MFU SETUP

4.1 Data Highway

The MFU uses RS-485, 2-wire, half duplex, Modbus RTU communications at various data rates. The

rules governing the installation and connection of an RS-485 highway should be observed at all times

to produce a successful installation. The RS-485 highway does not allow power to be transferred and

the MFU is powered from the actuator itself. The MFU can only report data when the actuator is

powered up.

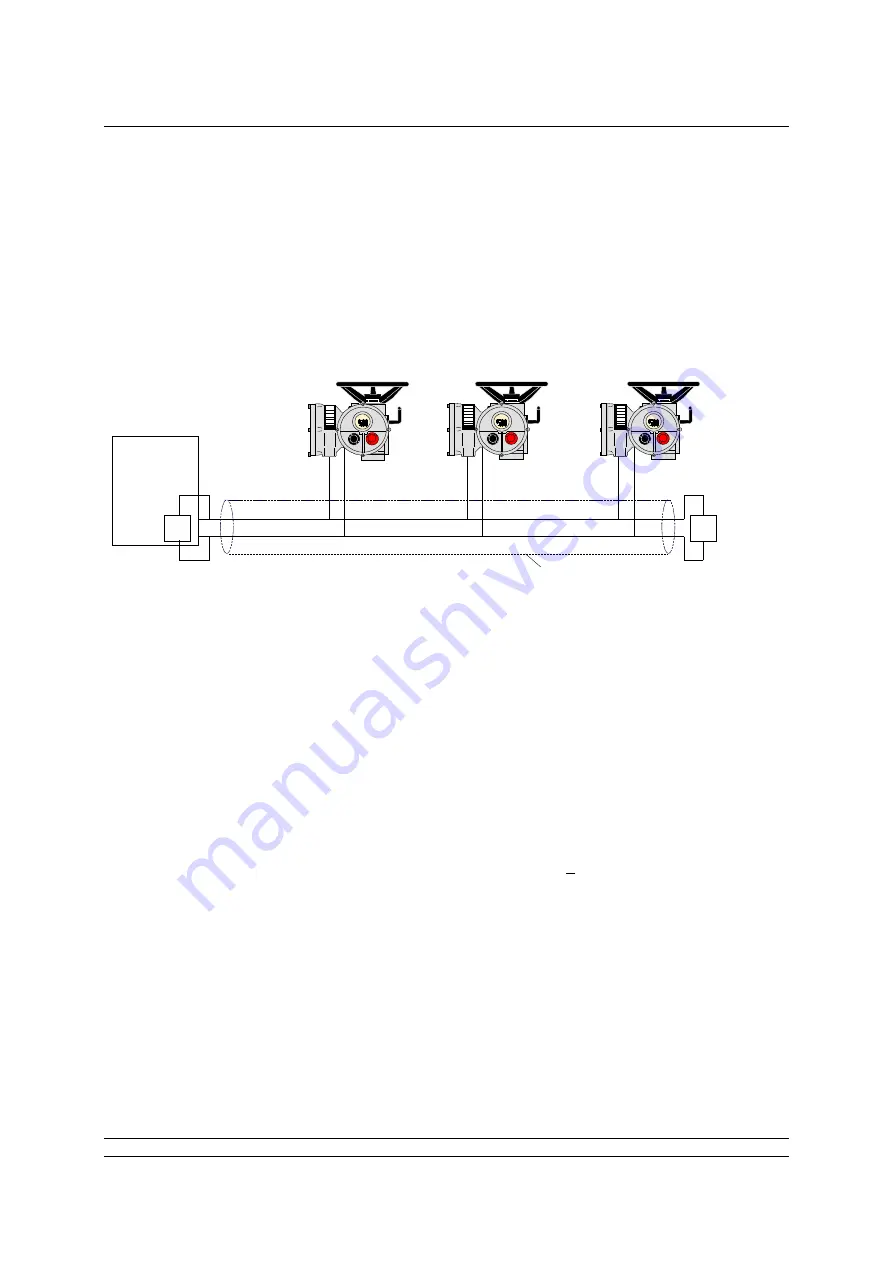

Fig 11: Typical RS-485 Data Highway

The data highway must be terminated with a proper termination resistor at each end. The highway

itself can use tapped spur or stub connections to the actuators but it is recommended to keep any stub

lengths to a minimum for successful operation. Alternatively, the connection can be made in and out of

each actuator in a daisy chain arrangement. The length of the highway and number of devices

connected will vary from project to project. The standard permits up to 32 devices to be connected on

a section, though one of these will be the PLC. If more devices are needed (up to the maximum

addressable of 247) then RS-485 repeaters may be added after each group of 32. The standard

default address used by the Modbus Module is 247.

The length of the highway will determine the maximum speed for the data transmission. The greater

transmission speeds are obtained at the lower lengths.

Although RS-485 requires only 2 wires for data transmission the standard also requires that all the

nodes on the network have a maximum common mode differential of +7 volts. This requires the

ground potential at all points to be within the 7 volt limit. If the equipment is distributed over a wide

area, or an area with poor ground conductivity, it may be necessary to connect a third wire between all

the nodes. Most successful installations use 3 wires and Rotork provides a ‘common’ terminal on the

actuator.

Since the data passes over a single 2 wire cable there are periods between messages when no

devices are actively driving the lines. In order to ensure that data continues to flow correctly after

these periods it is advisable to ensure the lines are biased to suitable voltage levels during the time

the line is idle. This is usually achieved by biasing at the PLC. The MFU contains internal biasing

circuits that ensure suitable levels are maintained on the line even with no device transmitting.

Terminator

T

2 wire highway

Screened cable

PLC

T