- 10 -

Ref No 790 / Art No 980790

We reserve the right to

make changes without notice

www.rotork.com www.remotecontrol.se

ROTORK SWEDEN AB

Box 80, Kontrollvägen 15, SE-791 22 Falun, Sweden

Tel: +46 (0)23-587 00 • Fax: +46 (0)23-587 45 • falun.info@rotork.com

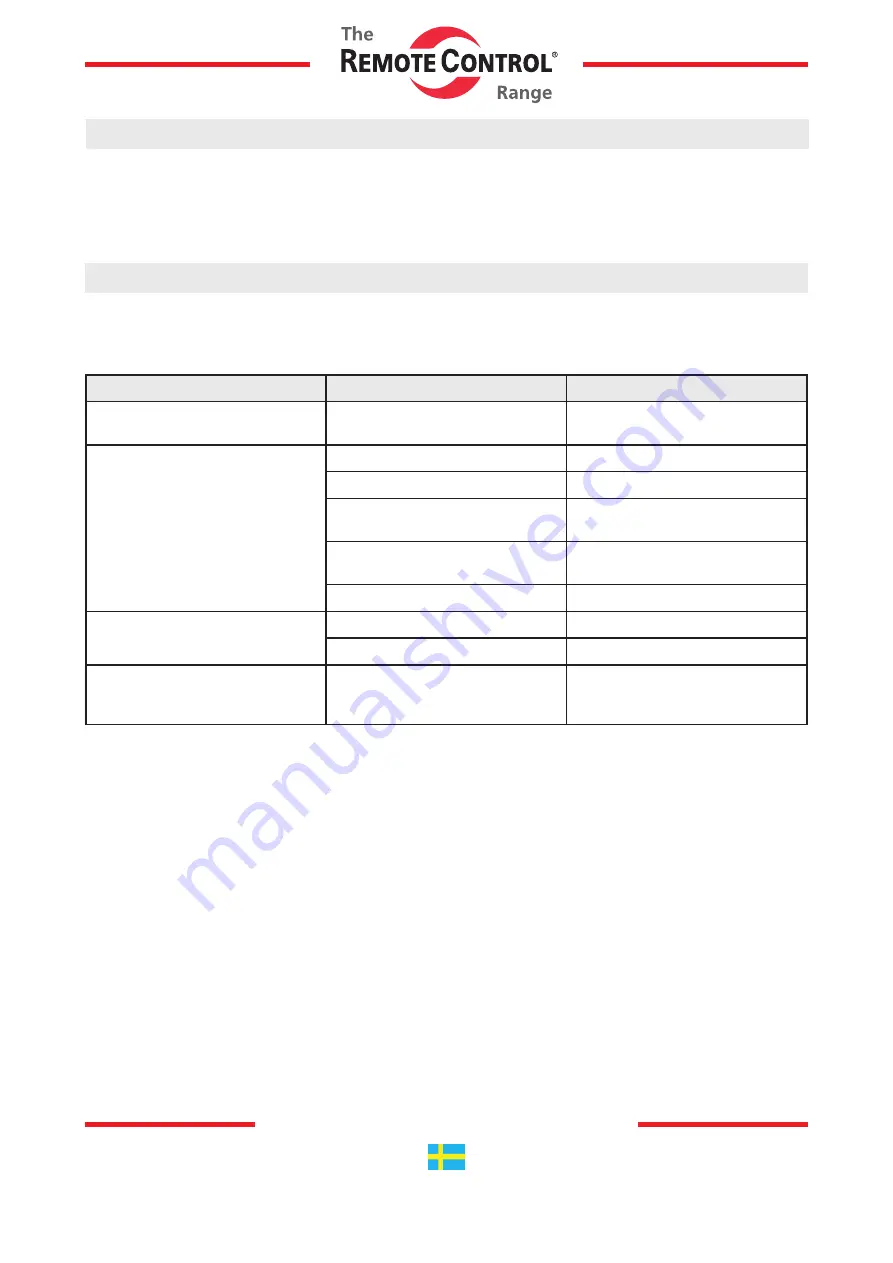

Troubleshooting

If the ACTUATOR fails to function correctly, first check for any mechanical / alignment problems, then check for any

electrical problems. See chart below for more information.

Problem

Cause

Sollution

Manual override not functioning

Gear failure

Disassemble the ACTUATOR

and replace the gear

When the motor

does not operate

Main power failure

Main power check

Motor/ Condenser damage

Replace Motor/ Condenser

Motor over heated and

thermal protector disengaged

Check frequency of operation or

JAMMED gears.

Wiring failure

Confirm unit is properly wired per

wiring diagram

Main board failure

Replace main board

LED lights not operating

LED board failure

Replace LED board

Main board failure

Replace main board

Actuator continues to move

even after the cam has

tripped the limit switch.

Main board failure

Replace main board

*

In addition to the above described mechanical / electric failures, other causes may be the reason for a failure based

on the site conditions. For more information please contact Rotork Sweden AB for consultation.

For faster service, please have all of the nameplate information avalibe.

Maintenance

It is recommended that the ACTUATOR be cycled every two weeks after purchase.

To minimize the effects of condensation in the ACTUATOR, it is recommended that the cable entries to be sealed

at the ACTUATOR and that the heater is energized.