Top Quality Valve Actuators

Made in Sweden

Pneumatic Multiturn actuator in Standard and ATEX design

Twin Power

- 1 -

www.rotork.com www.remotecontrol.se

Manual

Mounting

The Twin Power actuator works beyond reproach in all

positions. Valves with fluid media should if possible be

fitted in such a way that fluid leakage from the packing

box is not led from the packing box, through the stem, into

the stem nut and the actuator. It is desirable that the valve

stem should be assembled in an upright position. If this

cannot be done care should be taken to tighten the gland

regularly and change the box packing when necessary.

Grease the drive bush carefully and ensure that there is no

radial or axial diffraction between the drive bush and hub.

Check that the numbers of turns not exceed the permitted

turns on the chosen indicating bridge.

The last three numbers in the type denomination inside

the actuator cover, specifies the type of Indicator Bridge.

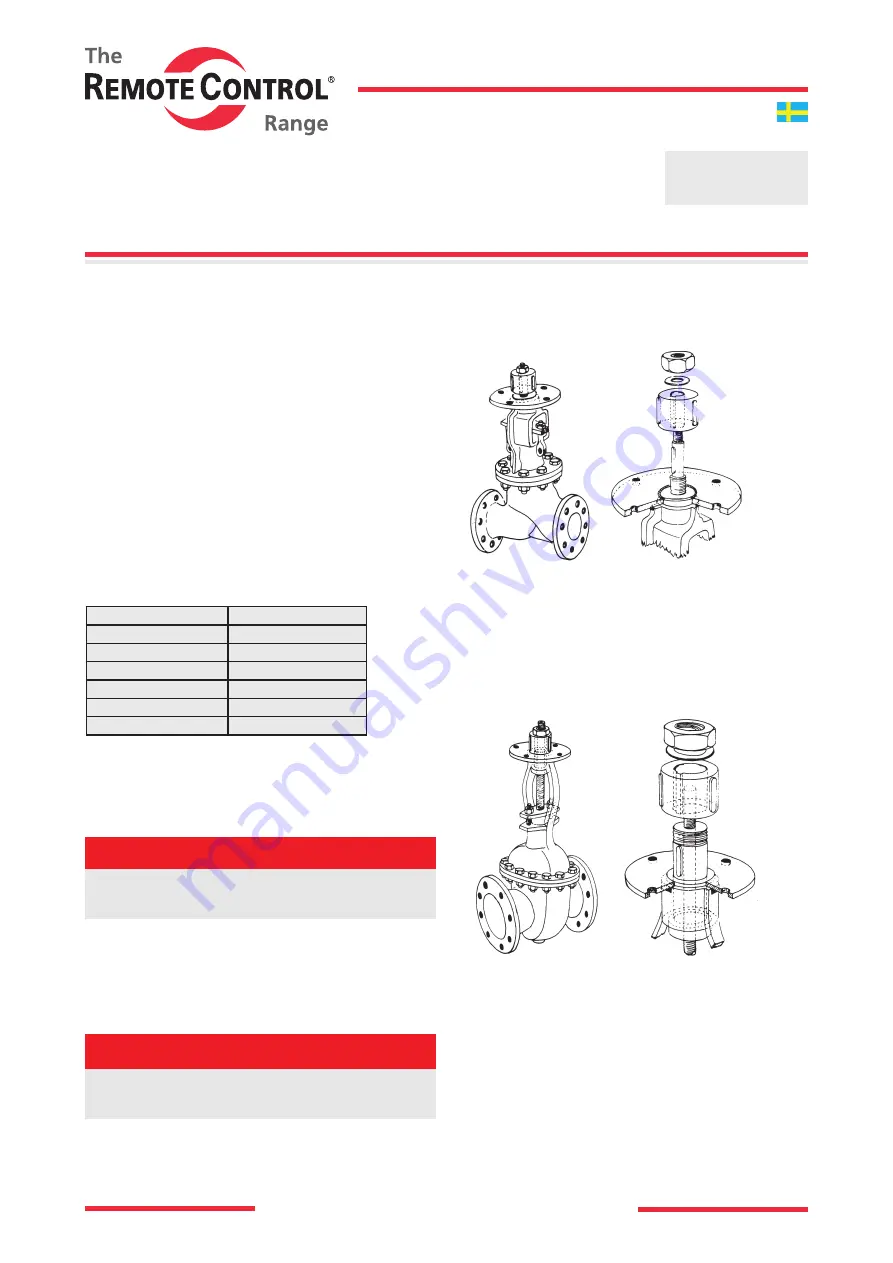

Assembly example

Indicator Bridge

Maximum turns

175

3,5 - 18

100

18 - 32

050

32 - 65

175S

65 - 155

100S

155 - 275

050S

275 - 550

In cases where the Twin Power actuator will be assem

-

bled on valves with rising stem and rising hand wheel, the

length of the hub must be minimum the length of the drive

bush axially movement.

Some practical advice

Ensure that the 3/8” air connections are positioned so as

to prevent dirt and liquids entering the motor. If necessary,

a short length of pipe should be fitted into each port, with

the end pointing downwards.

Driving

bush

Machined stem

end with key

Driving

bush

Stem nut

Valve designed with rising stem and hand wheel.

Valve with rising stem and non rising hand wheel.

Instead of the hand wheel a driving bush with keys is fitted

on the stem end. The driving bush rises axially corre

-

sponding to the valve rise. In this case an actuator must

be chosen with a hub length corresponding to the rise of

the bush.

A flange is mounted on the valve, and a driving bush with

keys fitted in the place of the hand wheel for transmission

of the turning movement to the stem unit.

Twin Power should be handled and operated by skilled

personnel.

WARNING!

Hand wheel must only be mounted during manual

operation.

WARNING!