- 2 -

E4L

E4

H

L

H

L

RC210

90

68

120

68

RC220-RC265

90

110

120

110

RC270-RC280,

RC88

100

160

130

160

RCG90-RCG100 155*

200*

185*

200*

Tabell 14pt bold

Bold på rubriker uppe, allt under ska vara regular.

Allt utom spalten med RC-förteckningar ska vara

centrerat i våg och lodrätt. RC-spalten ska vara

vänsterlagd.

Strl på texten varierar beroende på utrymme men

10pt är standard

www.rotork.com www.remotecontrol.se

Installation

Pressure control

The Remote Control Twin Power Actuator is designed for

a normal working pressure of 7 bar (100 psi), but it can be

satisfactorily operated between 4-8 bar (60-140 psi). The

supply air shall be dust and oil free. The air dew point shall

be -20 °C or 10 °C below the ambient temperature. The

maximum particle size must not exceed 40 μm.

The Twin Power actuator specified torque is direct

depending on the air supply pressure. In order to pro

-

duce a constant power output from the motor, an even

air pressure is required. The starting torque of the Twin

Power is approx. 50 % higher than the tightening torque.

If the tightening of the valve takes place at an air pressure

of 6 bar and the air pressure at opening is 5 bar, gives a

decreasing of the starting torque at a given relation to the

decreasing air pressure. If the air supply pressure fluctu

-

ates, a constant pressure regulator should be fitted in the

system. The regulator should be set so it gives a pressure

output equivalent to the lowest incoming pressure.

Oil mist lubrication

To increase the reliability of the Twin Power actuator, an oil

mist lubricator should be fitted as close as possible to the

actuator. For lubrication of the diaphragm motor, control

valve, and the moving parts of the operating cylinder,

an oil mist unit should be fitted not more than one meter

under the Twin Power actuator. At pneumatic operation

where the distance between the actuator and control panel

sideways and at falling pipe exceeding 10 meters, an oil

mist lubricator shall be fitted on the air supply pipe for

clockwise operation. The oil mist lubricator should be filled

with low viscosity oil. The guideline value for adjustment

of the oil mist lubricator is 1-2 drops/minute. Before the air

pipes connects to the actuator they should be cleaned by

air, so that no particles will cause operational disturbance.

To entirely avoid this risk an air cleaner can be fitted.

By new installations all of the air supply pipes shall

carefully be cleaned by air before connection to the

actuator and accessories.

WARNING!

Indicator bridge

Risk for injuries caused by crushing/squeezing and

electrical shocks when the actuator is energized by air

pressure and electricity with its cover off. Before open

-

ing, check that the compressed air and possible power

supply are disconnected. The cover should be mounted

when the actuator operates.

WARNING!

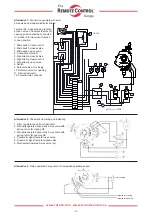

1.

Remove the cover.

2. Disconnect the top part of the terminal block, see

figure 1.

3.

Pull the cable through the cable gland and connect

according to desired wiring diagram.

4. Reconnect the terminal block. Make sure no cables

are close to any moving parts in the actuator.

5.

Put the cover back and tighten the screws.

6. Connect the actuator pneumatically and electrically.

7.

Verify the function of the actuator.

Figure 1

Before testing of the actuator:

Remove the two plastic caps that covers the breathing and

exhaust hole on the air motor.

Air connections for clockwise and anti-clockwise rotation

Operating

Check that the connection for incoming air supplies is cor

-

rect when the actuator operates with auxiliary valves, e.g.

solenoid valves.

When choosing auxiliary valve, i.e. pneumatic 3-way

valves, solenoid valves or hand operated valves, shall

these always be vented after completed operation.

When changing operation direction, the air pipe be-

tween the auxiliary valve and operating unit must be

vented before a new operation starts.

When manually operating with 3-way solenoid valves,

these shall be operated with 3-position switches with neu-

tral centricity. If other equipment is used, the same func

-

tion shall be obtained. At momentary impulse changes, i.e.

when the rotation direction must be changed rapidly, it is

recommended to use the connection according to alterna

-

tive on page 3.

Plastpluggar

borttages

Remove the

plastic caps

Connection for clockwise rotation

Connection for anti-clockwise

rotation