- 3 -

www.rotork.com www.remotecontrol.se

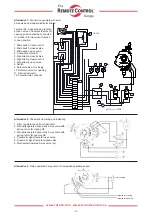

Alternative 1.

Connection example with sole

-

noid valve and standard indicator bridge

1. Filter, regulator and oil mist lubricator

2. Manually operated pneumatic 3-way valve with

spring return for closing NC

3. Manually operated pneumatic 3-way valve with

spring return for opening NC

4. Pneumatic signal lamp for open valve

5. Pneumatic signal lamp for closed valve

6. Mechanical operated 3-way valve (2x)

Terminal No. 5 has breaking function

at open valve. The solenoid valve for

opening position shall be connected

to terminal 5 for travel limit function

in open position.

1. Microswitch, travel control

2. Microswitch, closed valve

3. Microswitch, open valve

4. Connection terminal

5. Signal lamp, closed valve

6. Signal lamp, travel control

7. Signal lamp, open valve

8. Switch

9. Solenoid valve, for closing

10. Solenoid valve, for opening

11. Oil mist lubricator

12. Potentiometer, optional

7

6

5

s

CW

CCW

12

1

3

4

11

10

9

2

8

10

12

11

9

8

7

6

5

4

3

2

1

Option

Ref. No. 015228

Itemref

Designed by

Sheet

Scale

Date

Control

Title/Name, designation, material, dimension etc

Quantity

Item no, comment

1

2

3

4

A

B

C

D

E

F

A

B

C

D

E

F

1

4

2

3

This document is copyright legislationed protected and must not

, without permission from Rotork Sweden AB, be given or handed

over to any outsider. Trespass give rise to responsibility.

E

Draw. no.

Drawn

Weight [g]

Replace

Rev date

Art. no.

Smoothness where

not spec.

Measures not

tolerance spec.

Elschema indikeringsbrygga TP

015228 B

-

2014-06-05

2015-01-28

Mbi

Size A4

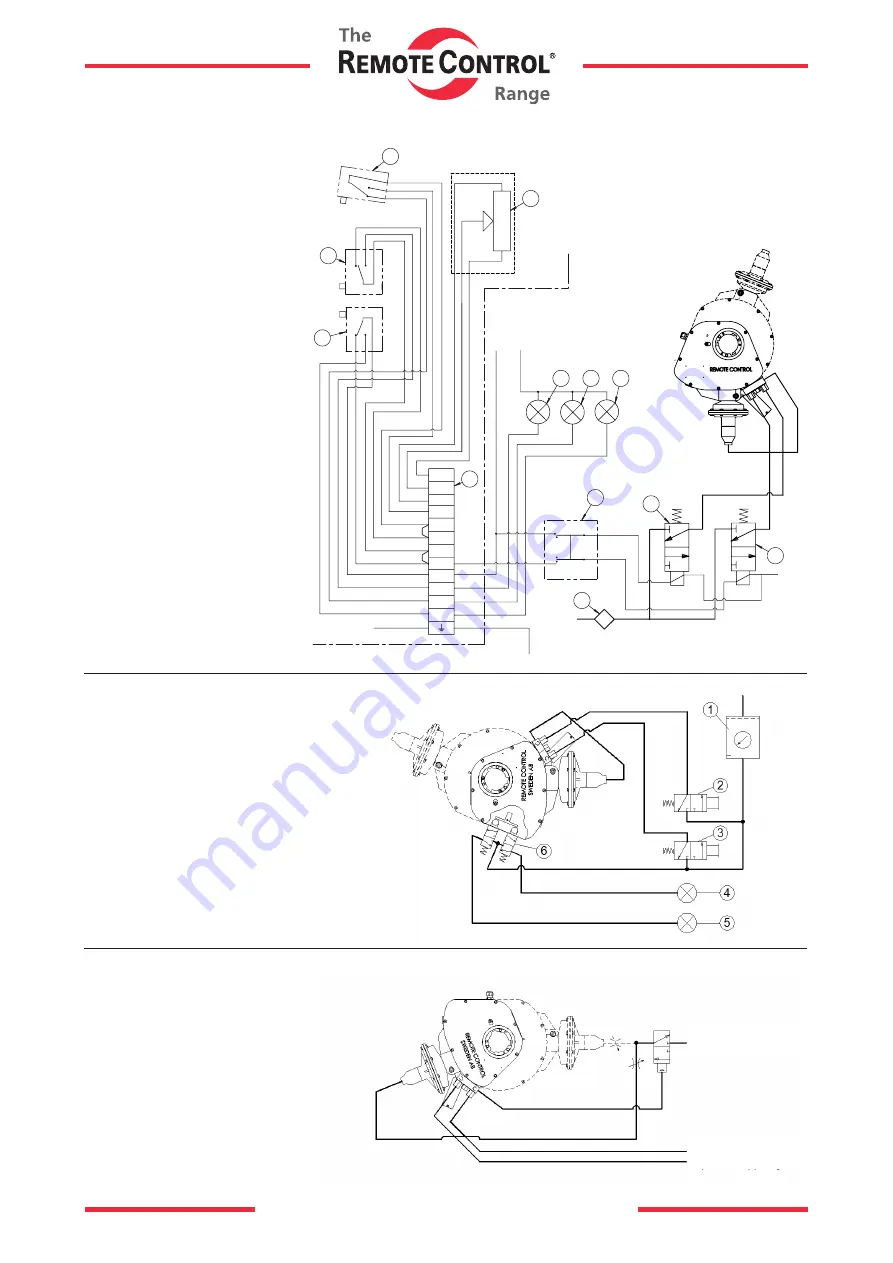

Alternative 3.

Piston operated 3-way valve for increased operating speed

Air supply

Impulse for closing

Impulse for opening

Alternative 2.

Pneumatic operating and indicating