- 4 -

E4L

E4

H

L

H

L

RC210

90

68

120

68

RC220-RC265

90

110

120

110

RC270-RC280,

RC88

100

160

130

160

RCG90-RCG100 155*

200*

185*

200*

Tabell 14pt bold

Bold på rubriker uppe, allt under ska vara regular.

Allt utom spalten med RC-förteckningar ska vara

centrerat i våg och lodrätt. RC-spalten ska vara

vänsterlagd.

Strl på texten varierar beroende på utrymme men

10pt är standard

www.rotork.com www.remotecontrol.se

Both the adjustable stops No. 1 and 2 are fastened by

screws in such a position of the slide rod, that they will be

affected by the slide block about 3 mm before this one has

reached its final position.

When the valve now is driven from the end positions the

latch will return into the neutral position by support of the

centering springs. When the latch has released the catch,

the operating cylinder (5:S1) will complete its stroke, and

the normal torque will be connected. The increased start

-

ing torque will be obtained by the fact that the motor shaft

(6:S1/5) changes point of attack on the operating levers

(2:S1/5).

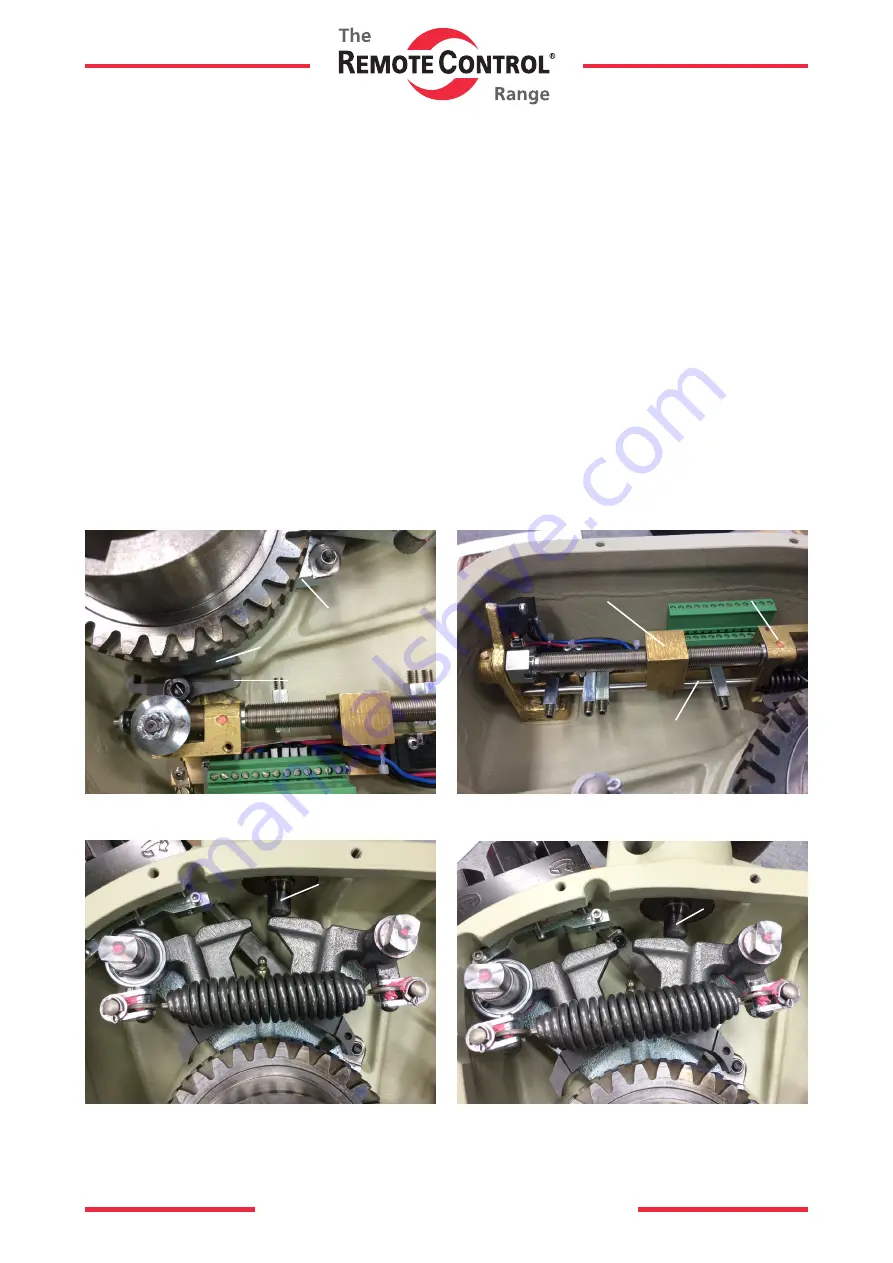

Figure 4 shows the position of the levers at the ”Starting”

Torque and figure 5 shows the position at the normal or

a ”Running” Torque. The increased starting torque will be

obtained only during the initial spindle revolutions counting

from each end position.

To make sure that the setting are sufficient it is recom

-

mended to operate the actuator a few times.

The function of the Indicator Bridge

The indicator bridge has several functions. First, the

latches (3:S1/26) accomplish the by 50 % increased

starting torque in both end positions. Secondly, the micro

switches of the bridge give signals which, when coupled

up to signal lamps, indicate ”open”, ”closed” and ”running”

condition. Further, it is possible to fit, as options, pneu

-

matic switches for open and closed position as well as

pneumatic or electric continuous indication.

The increased starting torque is obtained by a restriction

of the console movement (2:S1) when changing the rotary

direction, figure 2. By support of the catch (2:S1/12) in the

console this is kept in such a position of the latch (3:S1/26)

on the indicator bridge, that the effect will be the increased

starting torque in relation to the normal torque.

The latch (3:S1/26) is connected to the slide rod (3:S1/41),

figure 3. This slide rod is sliding in an axial direction by the

slide-block (3:S1/9-10), figure 3, in the last stage of the

valve operation.

2:S1

3:S1/26

2:S1/12

Figure 2

Figure 4

6:S1/5

2:S1/5

2:S1/5

Figure 5

2:S1/5

2:S1/5

6:S1/5

Figure 3

3:S1/9-10

3:S1/14

3:S1/41

4

3

2

1