- 7 -

www.rotork.com www.remotecontrol.se

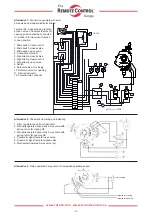

Twin Power actuators in

ATEX executions

0575 II 2 GD

Twin Power is ATEX certified in two executions. One with

mechanic indicator bridge and switch box 1990 and one

without indicator bridge but with gearbox and switch box

1990.

Surface temperature

Ambient temperature

°

C

Temperature class

70

T6

90

T5

125

T4

150

T3

A

B

C

D

E

F

A

B

C

D

E

F

2

1

3

4

5

6

7

8

1

3

2

7

6

8

4

5

Th

is

d

oc

um

en

t i

s c

op

yr

ig

ht

le

gi

sla

tio

ne

d

pr

ot

ec

te

d

a

nd

m

us

t n

ot

, w

ith

ou

t p

er

m

iss

io

n

fro

m

R

em

ot

e

C

on

tro

l A

B,

b

e

gi

ve

n

or

h

an

d

ed

o

ve

r t

o

a

ny

o

ut

sid

er

. T

re

sp

a

ss

g

iv

e

ris

e

to

re

sp

on

sib

ilit

y.

Measures not

tolerance spec.

Smoothness where

Title/Name, designation, material, dimension etc

Drawn

Itemref

Designed by

Quantity

Control

not spec.

E

Replace

Weight [g]

Rev date

Draw. no.

Sheet

Comment

Date

Scale

Art. no.

TP 114 m brygga för 1990

004610

2004-04-23

A.0

-

2004-04-23

stn

Size A3

Print date 2004-06-03

Gear wheel

Adjustment of switch box 1990

1. Dismount the lid.

2. Move the small gear wheel (see Fig above) sideways.

3. Follow point 2 to 9, page 5.

4. Close the valve.

5. Adjust the limit switch (for closed position) of the switch

box according to the instruction for the 1990 box.

6. Move the small gear wheel back.

7. Open the valve.

8. Adjust the limit switch (for open position) of the switch

box according to the instruction for the 1990 box.

9. Remount the lid.

Twin Power with mechanic

indicator bridge and switch box 1990

Twin Power with gearbox

and switch box 1990

Switch box 1990

When the actuator is mounted on the valve, possible limit

switches of the switch box, position transmitter and visual

indication shall be synchronised with the open and closed

valve position.

If the customer, at the registration of the order, has speci

-

fied the number of turns of the valve, this will be factory

preset. Only control and fine adjustment has to be done in

this case.

If the number of turns is not specified, or if factory preset

is unwanted, the equipment will be delivered with only

a functional test done. A complete adjustment has to be

done.

Control and fine adjustment of box 1990

The limit switches are the primary indication of the box.

In cases where limit switches are not used, the position

transmitter of the box is the primary indication.

In cases where visual indication is used, caution shall be

taken to avoid the hand to exceed the endpoints of the

scale in any occasion. If this happens the hand and the

through shaft can be damaged.

Fine adjustment of box

with

limit switches:

1. Make sure the valve is fully closed.

2. Attach suitable indication equipment to the limit switch

in the box indicating the closed position (view wiring

diagram sent with the box).

3. Turn the input shaft of the gearbox anticlockwise to

the position where the limit switch start to indicate. View

Figure B, pos. 1.

4. Mount the gear on the input shaft of the gearbox. View

Figure C, pos. 2.

Fine adjustment of box

without

limit switches:

1. Make sure the valve is fully closed.

2. Attach suitable indication equipment to the position

transmitter (view wiring diagram sent with the box).

3. Turn the input shaft of the gearbox anticlockwise to the

position where the position transmitter starts to indicate

closed position (normally 4.00 mA). View Figure B

pos. 1.

4. Mount the gear on the input shaft of the gearbox. View

Figure C pos. 2.