10

Commissioning

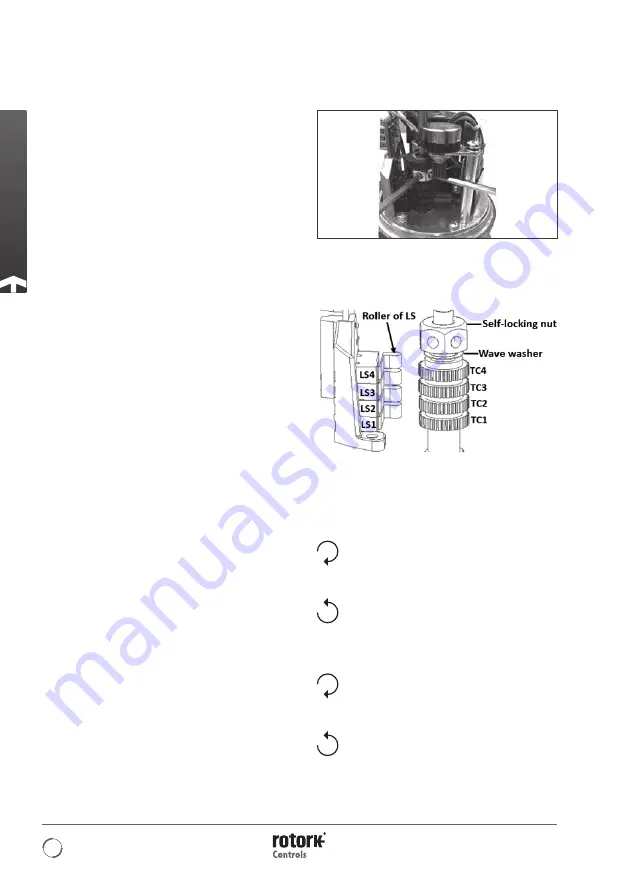

Type 2 - Cam adjustment for ROM 1/A

The following instruction is only applicable to

situation that the valve is clockwise for closing

(from the top view).

a. Turn power off.

b. Remove cover and unscrew the self-locking nut

anticlockwise twice approximately 60 degree

each time from position A to B as shown in

picture D by inserting 4.0mm Allen key into the

hole of self-locking nut.

Note: the Allen key should be flat head and

longer than 100mm.

c. Set fully open position by following item

1, 2, 3 below.

1. Use manual override to turn valve to the

fully open position.

2. Make sure the roller of LS1 is touching

the cylindrical surface of TC1.

3.

Case 1:

For ROM 1, rotate TC1 anti-clockwise

slowly until a light click is heard.

Case 2:

For ROM A, rotate TC1 clockwise

slowly until a light click is heard.

d. Set fully closed position by following item

1, 2, 3 below:

1. Use manual override to turn valve to the

fully closed position.

2. Make sure the roller of LS2 is touching the

cylindrical surface of TC2.

3.

Case 1:

For ROM 1, rotate TC2 clockwise

slowly until a light click is heard.

Case 2:

For ROM A, rotate TC2

anti-clockwise slowly until a light click

is heard.

e. Screw the self-locking nut clockwise to original

position (approximately twice 60 degree ).

f. Apply power to check the travelling position, if

the position is not correct, please repeat steps

a - f.

TC: Travel Cam

LS: Limit Switch

TC1: “OPEN”

Clockwise

ROM 1: Increase opening degree to fully open

ROM A: Decrease opening degree

Anti-clockwise

ROM 1: Decrease opening degree

ROM A: Increase opening degree to fully open

TC2: “CLOSE”

Clockwise

ROM 1: Decrease closing degree

ROM A: Increase closing degree to fully closed

Anti-clockwise

ROM 1: Increase closing degree to fully closed

ROM A: Decrease closing degree

TC3: Synchronous turn with TC1 (optional)

TC4: Synchronous turn with TC2 (optional)

ROM 1/A

Picture D: Travel from position A to B is about

60 degree

A

B