3

Redefining Flow Control

Health and Safety

This manual is produced to enable a

competent user to install, operate,

adjust and inspect Rotork ROM valve

actuators.

Only persons competent by virtues of their training

or experience should install, maintain and repair

Rotork actuators. Work undertaken must be carried

out in accordance with the instructions in this and

any other relevant manuals.

The user and those persons working on this

equipment should be familiar with their

responsibilities under any statutory provisions

relating to the health and safety of their workplace.

Due considerations of additional hazards should

be taken when using the ROM actuators with

other equipment. Should further information and

guidance relating to the safe use of the ROM be

required, it will be provided on request.

Electrical installation, maintenance and use of these

actuators should be carried out in accordance with

the National Legislation and Statutory Provisions to

the safe use of this equipment, applicable to the site

of installation.

For the UK:

Electricity at Work Regulations 1989

and the guidance given in the applicable edition

if the “IEE Wiring Regulations” should be applied.

Also the user should be fully aware of his/her duties

under the Health and Safety Act 1974.

For the USA:

NFPA 70 National Electrical Code is

applicable.

The mechanical installation should be carried out as

outlined in this manual and also in accordance with

relevant standards such as British Standard Codes

of Practice.

Actuator may start and operate without

warning, depending on the remote control

signal status and configuration.

Important Notices

a. Make sure the voltage is correct before wiring.

b. Power off before distribution or for

maintenance purposes.

c. Seal the casing and conduit entries after wiring

to prevent dust or water contamination.

d. Do not install when hazardous or explosive

gases may be present.

e. When more than one electric actuator needs

to operate simultaneously, please connect with

the individual cables.

f. Please connect the ground wire to PE or

inside the electric actuator.

g. The warranty period of our product is one year.

Duty performance

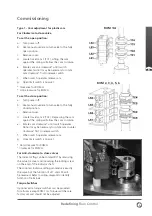

ROM perform Class A for standard type as table

shown according to EN 15714-2:2009(E).

BS EN 15714-2:2009

EN 15714-2:2009(E)

Rated Torque Ranges

Nm

Class A

On-Off

(cycles per hour

*

)

Up to 125

15

126 - 1,000

10

*

One cycle consists of nominal 90

o

angular travel

in both directions (i.e. 90

o

to open +90

o

to close)

based on an average load of at least 30% of the

rated torque, with the ability to transmit 100%

of the rated torque for at least 5% at each end

of travel, with a cumulative operating time not

exceeding 15 minutes in one hour.

Table 6 Part-turn actuator duty performances

According to EN 15714-2:2009(E), duty performance

for ROM is described as follows:

For ROM A and ROM 1, 2:

15 cycles per hour

For ROM 3, 4, 5, 6:

10 cycles per hour