5

Redefining Flow Control

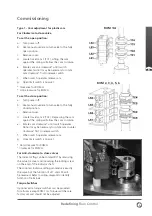

Setting the actuator stop bolts

Stop Bolts

There are no stop bolts fitted in the ROM 1,A.

Adjusting the stop bolts in and out will increase or

decrease the valve travel. It is recommended that

stop bolt adjustment be carried out by the valve

maker/supplier before the valve is fitted into the

pipe work. Once installed, the valve maker/supplier

should be consulted before stop bolt re-adjustment

is carried out. After resetting the stop bolts the limit

switches must be reset. The stop bolts are factory

set to give a nominal 90º travel. If fitted the stop

bolts are located near the gearbox base. Stop bolt

adjustment allows variation at each end position.

Screwing the bolt in reduces movement, out

increases movement.

For clockwise closing valves the right hand stop

bolt is the closed stop. The left is the open stop as

shown in the picture.

Adjustment for non-seating valve types

For closed and open stop position adjustments.

Undo stop bolt lock-nut. Move actuator and valve to

the required stopping position (it may be necessary

to unscrew stop bolt to allow more travel). Screw

stop bolt in until a stop is felt. Tighten stop bolt

lock nut.

Adjustment for seating valve types

For closed and open stop position adjustments.

Undo stop bolt lock-nut. Move actuator and valve

to the required seating position of the valve (it may

be necessary to unscrew stop bolt to allow more

travel). Screw stop bolt in until a stop is felt then

back off by two turns. Tighten stop bolt lock nut

Setting clockwise to close stop bolt

Setting anti-clock to close stop bolt