9

Redefining Flow Control

Commissioning

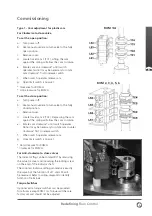

Type 1 - Cam adjustment for plastic cam

For Clockwise to close valve

To set the open position:

a. Turn power off.

b. Use manual override to turn valve to the fully

open position.

c. Remove cover.

d. Locate travel cam 1 (TC1). Lifting the cam

against the spring will allow the cam to rotate.

e. Rotate cam anti-clockwise* until switch

operates. Note: it may be necessary to rotate

cam clockwise

+

first to release switch.

f. When switch operates release cam.

g. Open limit switch is now set.

* Clockwise for ROM A

+

Anti-clockwise for ROM A

To set the close position:

a. Turn power off.

b. Use manual override to turn valve to the fully

closed position.

c. Remove cover.

d. Locate travel cam 2 (TC2). Depressing the cam

against the spring will allow the cam to rotate.

e. Rotate cam clockwise* until switch operates.

Note: it may be necessary to rotate cam counter

clockwise

+

first to release switch.

f. When switch operates release cam.

g. Close limit switch is now set.

* Anti-clockwise for ROM A

+

Clockwise for ROM A

For Anti-clockwise to close valves

The indicator flag can be rotated 90º by removing

the actuator cover and loosening the locking screw

on the end of the indicator shaft.

The counter clockwise setting procedure is exactly

the same but the function of LS1 and LS2 will

be reversed. Refer to wiring diagram to identify

function of terminals.

Torque Switches

Optional extra torque switches can be provided

for all sizes except ROM 1/A. Torque switches are

factory set and should not be adjusted.

ROM 1/A

ROM 2, 3, 4, 5, 6