ROMpak

Installation Manual

18

Commissioning

Optional Extras

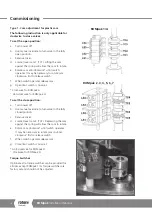

Current position transmitter (CPT) and

Folomatic combined PCB.

CPT

The CPT gives continuous indication of valve

position and is factory set to give 4 mA Close

20 mA Open.

Folomatic Proportional Control

The Folomatic proportional control sets the valve

position relating to an input signal. The Folomatic is

also factory set to operate 4 mA Close 20 mA Open.

For normal Folomatic control connect the internal

DC supply terminals 27 to 21 and 28 to 22. Refer to

wiring diagram for all connections.

For Folomatic or other remote control options

the main PCB control function switch 11 must

be set to ON.

Manual / Auto Selection

Using a switched input you can select between

Folomatic (Auto) and hardwired (Manual) operation.

This can be used in applications where it is necessary

for the operation to override the Folomatic to allow

full manual control of the actuator via hardwired

inputs. Refer to wiring diagram for all connections.

CPT and Folomatic Adjustment

The CPT and Folomatic are factory set and usually

need no adjustment. If the gearbox stop bolts have

been adjusted conduct the Initialisation process as

descibed on page 12.

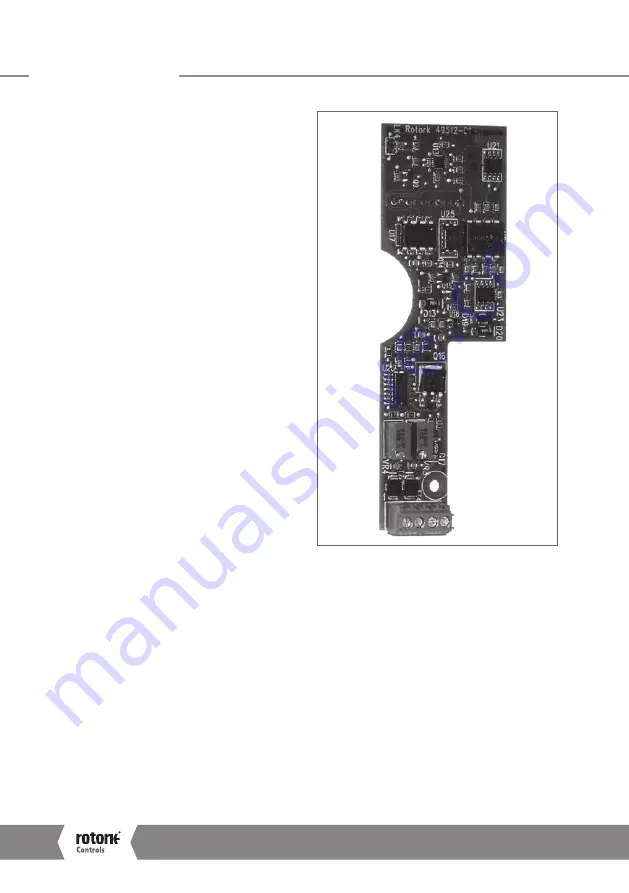

CPT Adjustment

Connect multimeter measuring mA to terminals

46 (+) and 45 (-). Move the actuator to the Close

position and adjust VR3 Zero potentiometer to

measure 4 mA output. Move the actuator to Open

and adjust VR4 Span potentiometer to measure

20 mA. The two adjustment potentiometers are

located on the CPT/Folomatic PCB and are identified

by text on the board. VR4 is mounted at the edge

of the PCB.

Current Position Transmitter (CPT) and

Folomatic combined PCB

Folomatic Adjustment

Position the red local control selector to Stop to

prevent actuator from moving. Set the control

function switch No.12 on the main PCB to

ON

.

Apply a 4 mA control signal onto terminals 48 (+)

and 47 (-) then rotate black control knob clockwise

to the Close position. Apply a 20 mA control signal

then rotate the control knob anti-clockwise to

the Open position. Return switch 12 to the

OFF

position. For high demand to close apply 20 mA

signal then rotate black control knob clockwise to

Close position. Apply 4 mA signal then rotate

anti-clockwise to Open position.