SI manual – Section: Basic Settings for Commissioning

25

7.4 Limits

NOTE:

Settings and operation must

be verified by electric operation and a

functional test of the actuated valve.

Connect to the actuator as described

in section 7.1. From the Position display

home screen press the

key. The

main menu will be displayed.

Navigate to Settings using the

keys and press

to select.

Y

Y

R

R

Fig. 7.4.1.

The settings menu will be displayed:

Settings

Limits

Stroke Tests

Indication

Control

Security

Defaults

Navigate to Limits using the keys

and press

to select.

The setting first selected to be

changed will require a password to

be entered, refer to section 7.2.

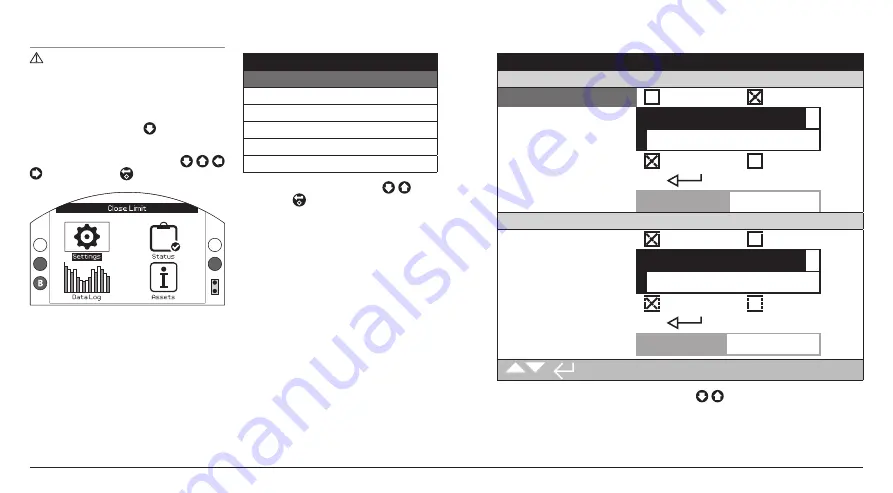

The limit settings are shown below with their factory default values:

Stopped

Close Settings

1 / 12

Action

Limit

Pressure

2 / 12

Pressure Limit

90%

3 / 12

Pressure Mid

0%

4 / 12

Semi Auto Setup

On

Off

5 / 12

Set Limit

6 / 12

Sensor Position

49%

Open Settings

7 / 12

Action

Limit

Pressure

8 / 12

Pressure Limit

90%

9 / 12

Pressure Mid

0%

10 / 12

Semi Auto Setup

On

Off

11 / 12

Set Limit

12 / 12

Sensor Position

49%

1 / 12

Function Action (1/12) is shown highlighted. Use

to scroll through functions.

Functions will be highlighted in turn.

Summary of Contents for Skilmatic SI 3

Page 39: ...39...