8

SI manual – Section: Storage

3. Storage

If your actuator cannot be installed

immediately, store it in a dry place until

you are ready to connect incoming cables.

If the actuator has to be installed but

cannot be cabled it is recommended

that the plastic transit cable entry plugs

are replaced with metal plugs.

Apart from the terminal and indication

cover, it is not necessary to remove any

electrical compartment covers in order

to commission the SI actuator.

Fill the reservoir with the correct

hydraulic fluid to protect the interior

from corrosion.

Visually inspect the equipment

periodically to identify any potential

corrosion. Repair as required.

Rotork cannot accept responsibility for

deterioration caused on-site once the

covers are removed.

Every Rotork actuator has been fully

tested before leaving the factory to

give years of trouble free operation,

providing it is correctly commissioned,

installed and sealed.

Do not store in temperatures beyond

the normal operating range as stated

on the data label.

4. Mounting the Actuator

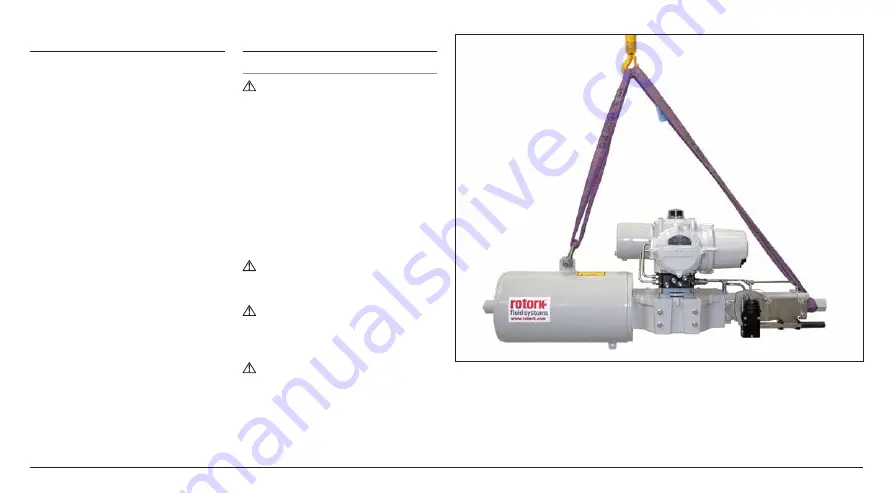

4.1 Lifting

NOTE:

Refer to section 11 Weights

and Measures for actuator weight.

Ensure the valve is secure before fitting

the actuator as the combination may

be top heavy and therefore unstable.

If it is necessary to lift the actuator

using mechanical lifting equipment then

certified slings should be attached as

indicated in figure 4.1.1.

At all times trained and experienced

personnel should ensure safe lifting

particularly when mounting actuators.

WARNING:

The SI actuator must

only be lifted from the spring can,

actuator body or hydraulic cylinder.

WARNING:

The actuator should be

fully supported until full valve shaft

engagement is achieved and the actuator

is secured onto the valve flange.

WARNING:

Do not lift the actuator

and the valve combination via the

actuator. Always lift the valve/actuator

assembly via the valve flange.

Each assembly must be assessed on an

individual basis for lifting.

Fig. 4.1.1. SI3 lifting: Slings attached to the lifting eye and hydraulic cylinder stop bolt cover.

Summary of Contents for Skilmatic SI 3

Page 39: ...39...