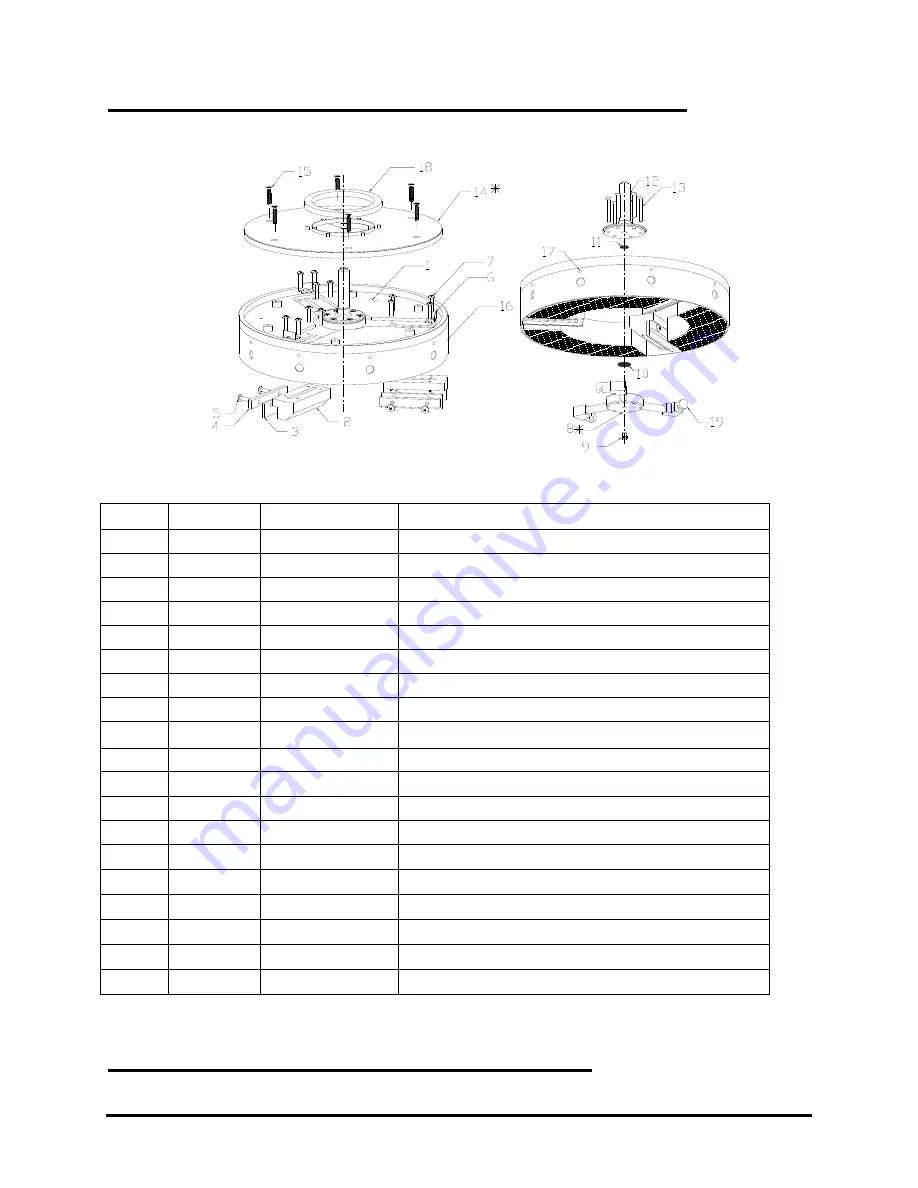

Hard Surface Brush Head

(RA-109B complete)

Vacuum System Maintenance Sprayer System Maintenance

ITEM # QUANTITY ROTOVAC P/N

DESCRIPTION

1

1

RP-264

VAC DISC W/ BRUSHES (BLUE STAGGERED)

2 3

RP-221

VACUUM/SQUEEGEE

SHOE

3 3

RP-223

SQUEEGEE

BLADE

4 3

RP-222A

SQUEEGEE

CLAMP

5 6

RV-437

SQUEEGEE

CLAMP

SCREW (#10-32UNF X 5/8)

6 3

RP-224

GASKET

RETAINER

7

12

RV-438

SCREW (#10-24UNC X 7/8)

8

1

RA-110

BRUSH SPRAYER ASSEMBLY

9 1

RP-269

VENT CHECK (FROM S/N 1803)

10 1

S-023

O-RING

11 1

RV-412

SMALL

O-RING

12 1

A-2329AL

MALE

SHAFT

(LH)

13 6

RV-609

FLAT

HEAD

SCREW

14 1

RA-106A

COVER/SEAL

ASSEMBLY

15 6

RV-497

FLAT

HEAD

SCREW

16 1

RV-435A

BRUSH

SKIRT

17 9

RV-450

SHEET

METAL

SCREW

18 1

RP-313

FELT

SEAL

19 3

S-0261

SPRAY

JET

(1.0)

360i TROUBLE SHOOTING GUIDE

14