-10-

Service

Preventive maintenance

performed by unauthorized

personnel may result in misplacing of

internal wires and components which could

cause serious hazard. We recommend that

all tool service be performed by a

Rotozip/Bosch Factory Service Center or

Authorized Rotozip/Bosch Service Station.

TOOL LUBRICATION

Your Rotozip tool has been properly lubricated

and is ready to use.

BEARINGS

After about 75-100 hours of operation, or at

every second brush change, the bearings

should be replaced at Bosch Factory Service

Center or Authorized Bosch Service Station.

Bearings which become noisy (due to heavy

load or very abrasive material cutting) should

be replaced at once to avoid overheating or

motor failure.

CARBON BRUSHES

The brushes and commutator in your tool have

been engineered for many hours of

dependable service. To maintain peak motor

efficiency, we recommend the brushes be

examined every two to six months. Only use

genuine Rotozip replacement brushes

specially designed for your tool.

If your tool runs sporadically, loses power,

makes unusual noises, or runs at a reduced

speed, check the brushes. Continuing to use

the tool in this condition will permanently

damage the motor.

Do not attempt to operate the tool with

broken, missing, or loose brush doors. If

the brush doors or brush door screws become

lost or damaged, please contact Rotozip

Customer Service for replacement parts.

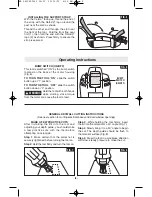

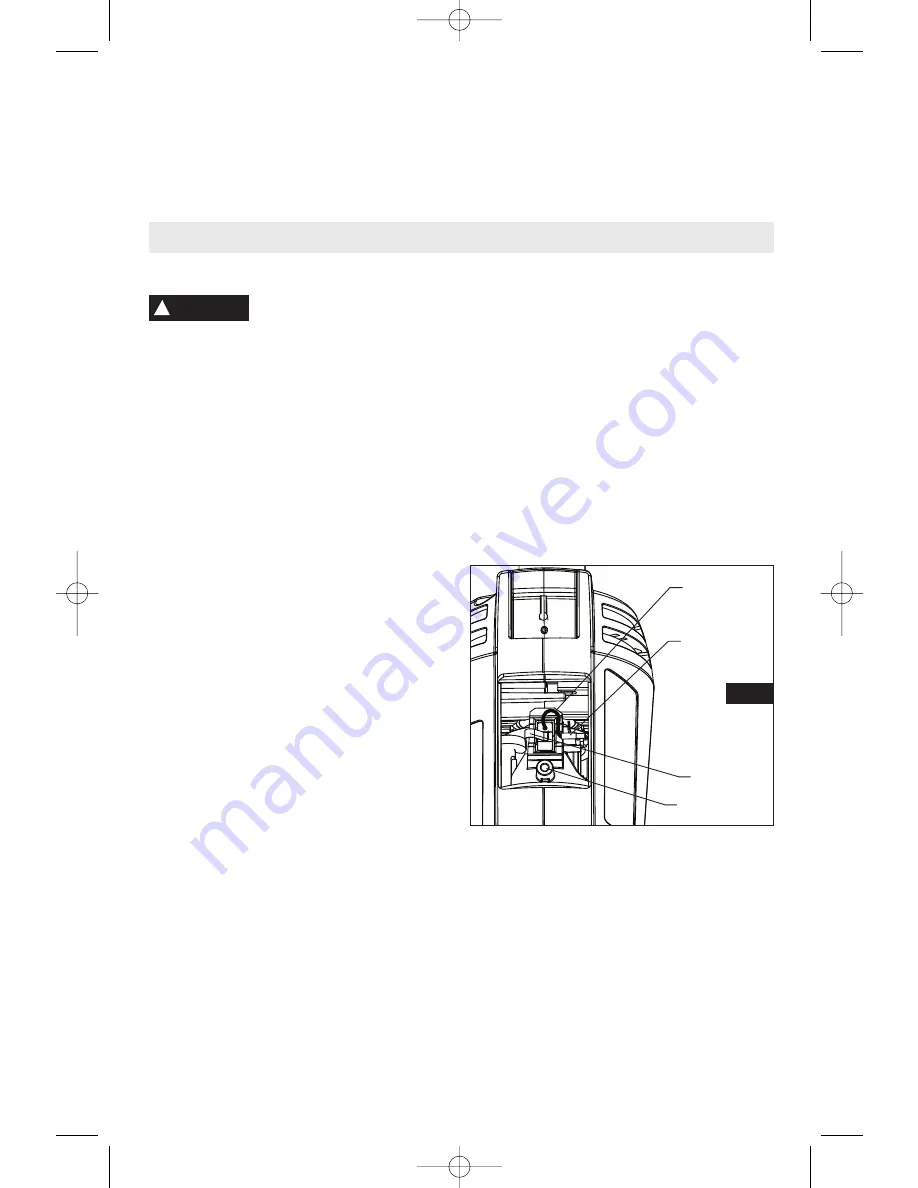

To Replace the Brushes

1. Disconnect the tool from the power supply.

2. Each door is held in place by a screw.

Using a screwdriver, loosen the screw by

rotating it counter-clockwise (Fig. 1). Be careful

not to lose the screw.

3. Using your fingernail, pry the brush door

loose and remove it from the tool.

4. In order to remove the brush, you must pull

back the spring that is holding the brush in

place. Using needle nose pliers, carefully pull

back the end of the brush spring and place it to

the side of the brush near the hole for the

brush door screw. Once the spring has been

moved, you can remove the brush by pulling

on the brush wire connector (Fig. 11). Be

careful not to bump the brush spring or

damage the brush wire connector. Make a

note of which side of the tool the brush was

removed.

5. Check both brushes. The brushes in your

Drywall Router will not wear at the same rate.

If either brush is less than 3/16" (4.8mm) long

or the worn end of the brush is rough or pitted,

replace both brushes. Place the new brush in

the brush holder, making sure the brush wire is

securely connected to its terminal inside the

tool. Fold the brush wire away from the screw

hole as shown. Place the end of the spring into

its original position.

6. Replace the brush doors. Be careful not to

over-tighten the brush door screw.

Maintenance

!

WARNING

THE DRYWALL ROUTER ONLY COUNTER-

CLOCKWISE to take advantage of the

“hugging” action of the bit along the contours

of the template. Remember to use a smooth,

continuous motion. The exception to this rule

applies to cutting window and door openings.

Since you are tracing around the inside of the

framing members, move the bit clockwise to

take advantage of the bits “hugging” action.

FIG. 11

SPRING

BRUSH WIRE

CONNECTOR

BRUSH

WIRE

SCREW HOLE

RZ 2610955525 10-07 10/11/07 8:19 AM Page 10