-15-

locks to engage square end of drive bit into

attachment.

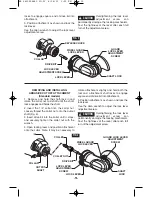

5. Position attachment as shown and lock the

lock lever.

Use the allen wrench to adjust the lock lever

adjustment screw.

Overtightening the lock lever

adjustment screw

can

permanently damage the locking mechanism.

Test the tightness of the lever after each full

turn of the adjustment screw.

!

CAUTION

LOCK LEVER

COLLAR

DRIVE BIT

KEYLESS CHUCK

WHEEL GUARD

LOCK LEVER

GUARD

LOCK LEVER

ADJUSTMENT

SCREW

SHAFT LOCK

LOCK LEVER

ADJUSTMENT SCREW

FIG. 2

LOCK LEVER

COLLAR

DRIVE BIT

COLLET NUT

COLLET

OUTPUT

SHAFT

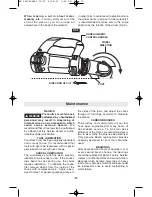

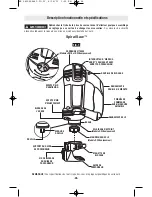

REMOVING AND INSTALLING

ABRASIVE CUT OFF ATTACHMENT

(Standard models)

1. Depress and hold the shaft-lock in and

rotate the collet nut and shaft until the shaft-

lock engages and holds the shaft.

2. Insert the 1/4” collet into the collet nut.

Loosely thread the collet nut onto the output

shaft (Fig. 3).

3. Insert drive bit into the collet until it stops,

and securely tighten the collet nut with the

wrench.

4. Open locking lever and position attachment

onto the collar. Note: It may be necessary to

rotate attachment slightly and hold both the

tool and attachment shaft locks to engage

square end of drive bit into attachment.

5. Position attachment as shown and lock the

lock lever.

Use the allen wrench to adjust the lock lever

adjustment screw.

Overtightening the lock lever

adjustment screw can

permanently damage the locking mechanism.

Test the tightness of the lever after each full

turn of the adjustment screw.

WHEEL GUARD

LOCK LEVER

GUARD LOCK LEVER

ADJUSTMENT

SCREW

SHAFT

LOCK

LOCK LEVER

ADJUSTMENT

SCREW

FIG. 3

!

CAUTION

RZ 2610954840 07-07 8/16/07 3:55 PM Page 15